Web service gathers train data via HPA interface / Introduction of handhelds planned

Digital transformation in the port of Hamburg: Effective immediately, the tank terminal operator Evos uses a digital connection to the Hamburg Port Authority (HPA). Via a new interface to a cloud communication service, the tank terminal and the HPA now exchange train data fully automatically – manual entry and transfer by employees are no longer necessary. The solution was developed and implemented by the specialist for tank terminal software solutions, Implico.

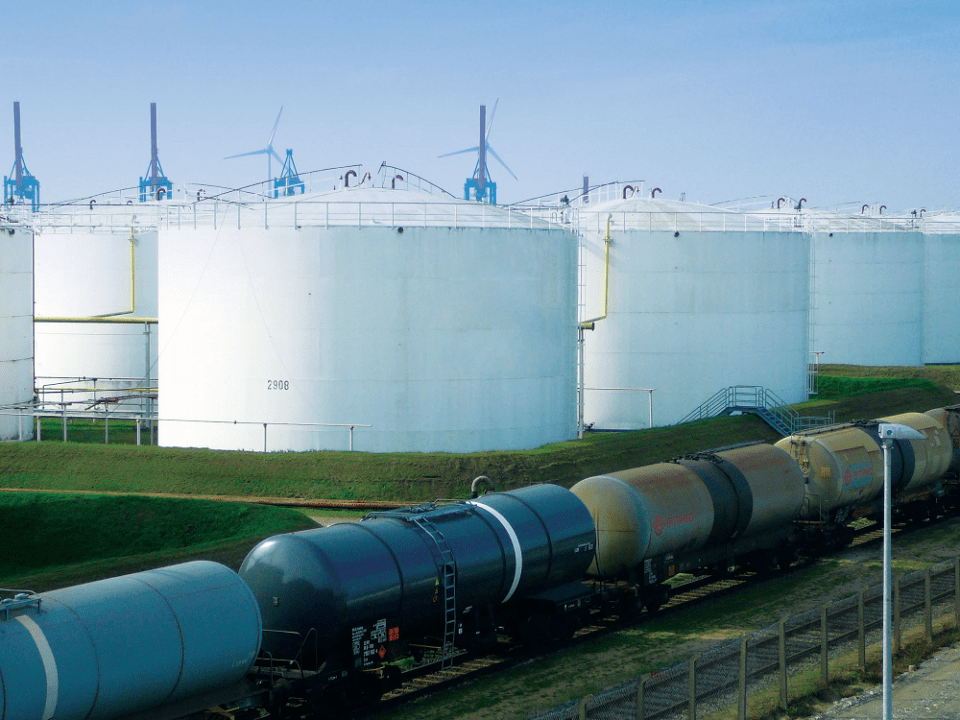

Every year, thousands of railcars are handled at the Evos terminal in the port of Hamburg. These ensure the rail-based supply of various hydrocarbon products from different refineries and terminals. Until now, an incoming freight train meant a lot of manual work for the Evos team: The employees had to record each arriving railcar by hand, including the associated master data. Based on this information, they generated the required unloading order. This process was both time-consuming and error-prone. Now that the HPA and the terminal management system OpenTAS “Blue Edition” used by Evos are connected, the terminal operators receive all information about incoming freight trains in advance: The data is imported into the system via an interface and the unloading order is generated automatically.

To further digitalize the remaining safety check of the railcars, Evos has planned the introduction of additional mobile devices. These handhelds will be integrated into the terminal management system. They allow the terminal crew to check the railcars directly and digitally – from the master data to the sequence of the wagons to the visual security inspection via checklist. This increases safety as the employees cannot overlook anything. In addition, the use of handhelds eliminates redundant tasks and supports the field staff optimally with state-of-the-art technology. Consequently, it makes the process much more efficient.

Sebastian Palandt, Manager IT and OT at Evos Hamburg, explains: “With the new interface and the planned handhelds, we take a big step towards the further digitalization of our processes. For the deliveries that reach us by rail, we now receive all relevant information in advance – be it the actual wagon data, the order data or the details of the products loaded. Furthermore, the usage of mobile devices directly on site at the train significantly increases the level of transparency and security”.

The newest technology for future-proof digitization

The data exchange between the HPA system TransPORTRail and the terminal management system OpenTAS used by Evos is carried out via the innovative web service “iGOS Data Exchange” from the tank terminal IT specialist Implico. In the implementation of the project, the experts used many innovations, such as the state-of-the-art cloud technologies Docker and Kubernetes.

Thomas Roller, Head of Sales, Marketing & Business Development at Implico, outlines the background: “Implico develops cloud-based solutions that find usage along the entire oil and gas supply chain. Since these web services are extremely flexible, companies can implement them quickly and use them easily. The rail interface used by Evos is part of a broad portfolio and marks an important step in the digitalization of tank terminals”.

About Evos Hamburg

Evos is a growing international and independent energy storage company, operating a network of premium tank terminals in Europe with a combined storage capacity of 2.5 million m3. The Evos Group offers its customers tailor-made solutions for the storage and distribution of both petroleum and chemical products.

Evos Hamburg has the ideal location in the third largest port in Europe with direct access to the European motorway and rail network. It is strategically connected to the most important North and East European markets. Hamburg is therefore an ideal hub for Evos and its customers to supply the German hinterland as well as the Central and Eastern European markets.

Evos Hamburg has more than 60 years of experience and competence as a service provider in the careful and qualified handling of sensitive and liquid bulk goods. With a strong focus on safety and sustainability, Evos Hamburg guarantees the safe, efficient and clean storage of petroleum products and special chemicals required for a variety of economic and everyday activities. The comprehensive range of services and product know-how meets the high demands of Evos Hamburg’s customers and their products.

About Implico

The Implico Group optimizes logistics and business processes for oil and gas downstream companies. The international consulting and software company with its headquarters in Hamburg, Germany, has subsidiaries in North America, Europe and Asia. Founded in 1983, the company today employs around 250 staff.

Implico provides consulting services, data services and software solutions for the entire supply chain – from forecasting, order entry, dispatching and tour optimization to data collation and invoicing. Leading oil and gas companies all over the world trust in Implico’s industry expertise and high-performance IT solutions including OpenTAS, iGOS, and the SAP downstream solutions SAP SDM and SAP RFNO (both available as Business Suite or S/4HANA version).

OpenTAS automates the storage and transportation of hydrocarbons for refineries, tank farms, and service station networks. iGOS (Implico Global Operation Services) offers innovative downstream solutions out of the cloud. SAP SDM (Secondary Distribution Management) steers and optimizes the complete order-to-cash process. SAP RFNO (Retail Fuel Network Operations) automates all payment and quantity flows of service station networks.

Implico is a Microsoft Gold Partner, a Software Development Partner of SAP and a member of the Oracle PartnerNetwork. In the field of terminal automation systems, Implico is market leader in Europe, Middle East and Africa (ARC market study 2018). The company has been recognized for its products and services on numerous occasions. It was named, for example, “Best Oil & Gas Software Specialists” in 2017 and received the Tank Storage Award as “Best Terminal Supplier” in 2018.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.

![Why Enhanced Geothermal Energy Could Be Your Next Smart Investment [2025 Guide]](https://b1006343.smushcdn.com/1006343/wp-content/uploads/2025/06/Why-Enhanced-Geothermal-Energy-Could-Be-Your-Next-Smart-Investment-2025-Guide-500x280.jpg?lossy=2&strip=1&webp=1)