Introduction

Final documentation for project equipment and materials, typically submitted as a Manufacturing Record Book (MRB) or Turnover Package (TPK), is critical for ensuring project success. Properly reviewed documentation can save frustration, money, and time. After project close-out, locating necessary data can become difficult or impossible. This may be because documents:

- Are stored in voluminous repositories that are difficult to search;

- Make improper use of management software; or,

- Use no identification codes or transmittals.

A project usually involves multiple contractors, suppliers, and vendors (suppliers), each with numerous MRBs/TPKs. Success hinges on developing and following a detailed review plan, such as a corporate or project instruction or including requirements in the project execution plan (PEP).

Background

MRBs/TPKs:

- Are reviewed for final acceptance by personnel from a consulting or engineering & procurement (E&P) companies, engineers of record (EOR), owners, end-users, or a combination;

- Are submitted as one or more volumes per equipment, material, or package type per the procurement documents (i.e., contract or Purchase Order [PO]);

- Contain quality control (QC) and technical data or other records submitted as a single digital file; duplicate or hard copies are obsolete;

- Have content and format specified in the procurement documents using a Supplier/Vendor Drawing and Data Requirements (SDDR/VDDR), Supplier Document List (SDL), Turnover Package Checklist (TPC), or similar form; and,

- May be reviewed by engineering, materials, operations & maintenance (O&M), quality, and other personnel or subject matter experts (SMEs).

The Problem

The requirements for MRBs/TPKs are specified and reviewers are identified (Section 1.1). However, without detailed instructions, project personnel might resort to inconsistent methods, risking project failure.

PRO TIP 1: Ensure your project includes instructions detailing how and by whom MRBs/TPKs should be reviewed. If no such instruction exists, this article (see below) provides guidelines to get started.

PRO TIP 2: Ensure your project includes instructions detailing MRB/TPK content and formatting requirements. Procurement documents should specify project requirements clearly. Require cover sheet and TOC submission for review before the complete MRB/TPK is submitted to avoid delays, inadequate information, and rework.

RELATED FACT SHEET: Top Five Challenges for Reviewing WPSs.

Discussion

Key considerations for MRB/TPK review include:

- Reference Material;

- Review Type;

- Supplier Experience;

- Personnel Experience;

- Project Experience; and,

- Equipment or Industry Type.

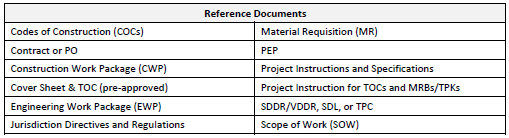

Reference Material

Reviewers should have access to all relevant procurement and project documents (see next table). Review Type

Review Type

Various methods can be used to review an MRB/TPK, depending on equipment complexity, cost, criticality, and project specifications. Three methods are:

- Record Review;

- Summary Review; and,

- Comprehensive Review.

If corrections are required, the MRB/TPK may be returned for rework by the supplier. The reviewer can also make simple corrections, such as applying or inserting missing information or altering formatting.

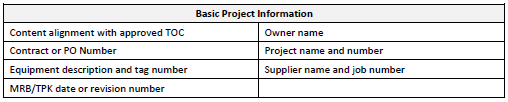

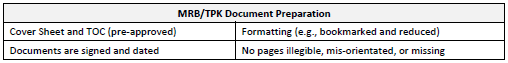

For each review method, basic project information must be verified to ensure it is complete and correct. TOC pre‑approval is very useful for this purpose because it helps ensure acceptance with the first submittal (yeah, no rework!). The next table lists basic information (as applicable). The MRB/TPK content is then reviewed for acceptance, as described in the Record Review and Comprehensive Review.

The MRB/TPK content is then reviewed for acceptance, as described in the Record Review and Comprehensive Review.

Record Review

Accept and file the MRB/TPK as-is without any detailed review. This is not recommended for most equipment and materials.

For Record Review, an MRB/TPK is obtained but no actual review is performed since it is accepted and filed as-is. However, most equipment and materials contain vital QC or technical information necessary for construction, integrity assessments, O&M, or replacement‑in‑kind (RIK). Therefore, conducting this type of review is not recommended. If an MRB/TPK is specified, the reviewer should ensure that the requirements were fulfilled, at minimum through a summary review.

Summary Review

Verify that the MRB/TPK content and formatting are complete and correct. This is suitable for a historical supplier or standard SOW.

A Summary Review verifies that the MRB/TPK content and formatting are complete and correct. Depending on the contents, number of pages, and the reviewer’s experience, this process may take about an hour. This approach may be appropriate for a historical supplier or when the SOW is standard (e.g., off-the-shelf designs or products) and the supplier’s personnel are familiar with project requirements. A Summary Review comprises two steps:

1. The MRB/TPK document preparation is verified as acceptable, including for data shown in the next table. A common mistake occurs when double-sided pages are scanned as single-sided, resulting in missing even‑numbered pages (i.e., pages 2, 4, 6, 8, and so on).

A common mistake occurs when double-sided pages are scanned as single-sided, resulting in missing even‑numbered pages (i.e., pages 2, 4, 6, 8, and so on).

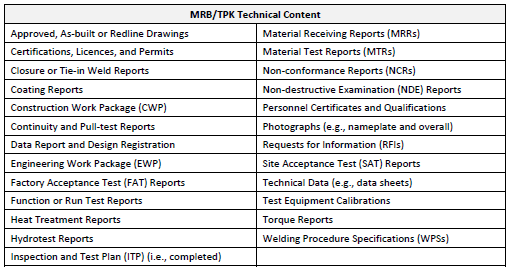

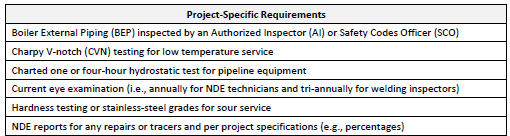

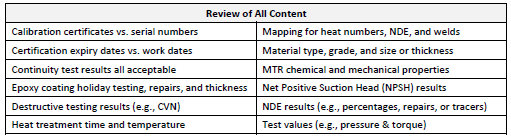

2. The MRB/TPK technical content is verified as acceptable, including for data shown in the next table. The next table lists non-standard or project-specific requirements and problematic data that may be incorrect or overlooked. Hence, it should be verified using a comprehensive review).

The next table lists non-standard or project-specific requirements and problematic data that may be incorrect or overlooked. Hence, it should be verified using a comprehensive review). Comprehensive Review

Comprehensive Review

Conduct a detailed, line-by-line, and page-by page review. This is suitable for foreign or new suppliers or non-standard SOWs.

A Comprehensive Review verifies the MRB/TPK content is complete and correct, and all details are fully compliant with the COC, procurement documents, and other requirements. Depending on the contents, number of pages, and reviewer’s experience, this process may take from four to eight hours. This approach is suitable for a foreign or new supplier, or when the SOW is non‑standard (e.g., custom designs or products), or the supplier’s personnel may be unfamiliar with Canadian or United States (US) jurisdictional (i.e., province or state), or project requirements.

In addition to the two steps described for a summary review, a line-by-line and page‑by‑page review of all content, including specific data, is conducted. This includes all content mentioned in the next table. Supplier Experience

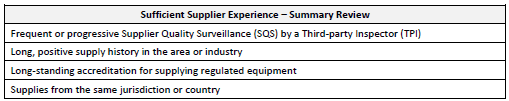

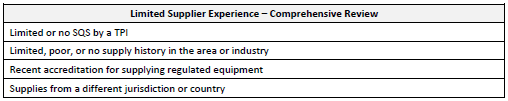

Supplier Experience

Determine review method based on supplier experience (see next table). The MRB/TPK may be suitable for a comprehensive review if the supplier has limited experience (see next table).

The MRB/TPK may be suitable for a comprehensive review if the supplier has limited experience (see next table). PRO TIP 3: It is always value-added to have the TPI review QC and other documentation both progressively and when compiled for the MRB/TPK, if not the completed document itself. While this may require an additional inspection visit, it is usually beneficial.

PRO TIP 3: It is always value-added to have the TPI review QC and other documentation both progressively and when compiled for the MRB/TPK, if not the completed document itself. While this may require an additional inspection visit, it is usually beneficial.

Personnel Experience

Experienced personnel can review MRBs/TPKs more effectively and efficiently but involve less experience personnel in mentorship opportunities where possible.

More experienced and knowledgeable personnel may be able to review MRPs/TPKs quickly because they are very familiar with common challenges, equipment and materials, review procedures, and project requirements. On the other hand, less experienced or knowledgeable personnel may need additional time to review MRPs/TPKs, access reference material, and ask questions of more experienced personal to confirm their understanding.

Project Experience

Review complexity depends on the project’s scope, materials, and technologies. Familiar projects are less challenging; MRBs/TPKs for exotic or unfamiliar projects require more thorough review.

A project may involve multiple organizations, each using personnel with varying levels of experience and expertise. There might be numerous personnel from each organization, or there may only be limited involvement, such as personnel from the owner and supplier.

Is the project extensive, spanning several years? Or is it compact and planned for completion in a few months or weeks?

Does the project deal with familiar materials or technologies for project teams, like carbon and stainless steels commonly used in the oil and gas (O&G) industry? Or does the project involve unfamiliar materials or technologies that are exotic for project teams, like aluminium for cryogenic service or titanium for corrosive or high-temperature applications?

The level of experience and knowledge within the project teams significantly influences the complexity of MRB/TPK reviews. Generally, the more experienced and knowledgeable the teams are, the less challenging these reviews will be, and vice versa.

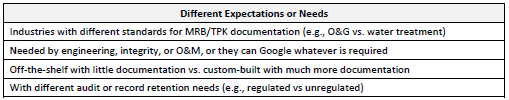

Equipment or Industry Type

Different equipment and industry types have distinct MRB/TPK document standards and needs. And a project may procure equipment or materials from various sources (see next table). An industry may be well-established in a certain area or county but not in another. For example, Australia has been the world’s largest Liquid Natural Gas (LNG) exporter since 2020, with 10 operating LNG facilities. [1] Canada, on the other hand, has 7 LNG export projects and 1 infrastructure project in various stages of development, with 4 operating liquefaction facilities, and 2 operating import facilities. LNG Canada’s export facility in Kitimat, BC, will be Canada’s first large-scale LNG facility with exports expected to start by 2025. [2]

An industry may be well-established in a certain area or county but not in another. For example, Australia has been the world’s largest Liquid Natural Gas (LNG) exporter since 2020, with 10 operating LNG facilities. [1] Canada, on the other hand, has 7 LNG export projects and 1 infrastructure project in various stages of development, with 4 operating liquefaction facilities, and 2 operating import facilities. LNG Canada’s export facility in Kitimat, BC, will be Canada’s first large-scale LNG facility with exports expected to start by 2025. [2]

Although LNG is related to the O&G industry, it is a distinct industry with different expertise and requirements. Hence, LNG project requirements that may be familiar in Australia may have been less well-known in Canada until recently. The same applies to the emerging hydrogen industry, which is new in many areas but well established in others, such as Alberta, a top 10 global hydrogen producer. [3]

Conclusion

Avoid a one-size-fits-all approach for MRB/TPK reviews. Detailed, project-specific instructions ensure completeness, correctness, and resource efficiency. Proper review preparation saves frustration, money, and time—keys to project success.

For further assistance with your MRB and TPK needs, contact the KT Project.

Figures

- Manufacturing Record Book (MRB)/Turnover Package (TPK) Submittal, https://www.accessrecordsmanagement.co.uk/wp-content/uploads/2019/09/Electronic-Document-Storage-1024×585.jpg

References

- Australasian Centre for Corporate Responsibility. Australia’s LNG growth wave – did it wash for shareholders?. https://www.accr.org.au/downloads/accr_lnggrowthwave_271123.pdf

- Government of Canada, Natural Resources Canada. Canadian liquified natural gas projects. https://natural-resources.canada.ca/energy/energy-sources-distribution/natural-gas/canadian-liquified-natural-gas-projects/5683

- Government of Alberta. Hydrogen development – Overview. https://www.alberta.ca/hydrogen-development-overview

Notes

- This article was peer-reviewed by Gagandip Grewal, PMP.

Roy O. Christensen is a Welding Engineering Technologist who has over 35 years’ experience with oil and gas, pipelines, and other projects. He has authored countless instructions, manuals, plans, proposals, reports, specifications, and other documents that continue to drive success for many projects. He is the founder of the KT Project, which saves organizations significant money and time, by providing key resources to leverage expert knowledge transfer for successful project execution.