3D printing technology, also termed additive technology, has played a huge role in the aerospace and aircraft industry, even after being a relatively new technology. Several new industries are now opening their door and integrating this technology, especially the oil, maritime, and petrochemical industry. Additive technology could make the oil industry efficient by making the extraction process easier and more cost-effective, which would generally impact the economy of every country.

With Massivit 3D printing, industries can reduce waste time now where one had to wait for a long time for the equipment to be sourced before. This technology is now considered to be the biggest driving force toward a positive economy and production, and for your benefit, here is how 3D printing could help solve the supply chain issues affecting the petrochemical and oil industry.

Reduces Pressure on Storage and Inventory

Additive technology can help you a great deal not only by saving lead time but also by reducing the storage space cost. You do not have to wait long while sourcing parts and machinery, vessels, or rigs; rather, now the digital files would be replacing the physical products so as to keep your operations functional. In the oil industry, a huge amount of capital goes to waste by investing in inventory that would never be used but is kept as a precaution; they become superannuated over time. With 3D printing, you gather the parts you need at that specific time.

For example, you need a part in Brazil, but it is miles away, and it would take months for the inventory to reach Brazil. With digital files stored in the computer, the data would reach the nearest additive company, which would help with the production of the part and reduce operational downtime. The supply chain can get costly for equipment that is urgently needed for smooth operation; AM technologies help you with on-demand production without any retooling. This way, oil companies can stay agile and competitive without investing millions.

Plays a Huge Part Towards Minimizing Carbon Footprint

The whole world is keen on reducing carbon footprint, and AM technology has helped industries take a positive stance towards it. With additive manufacturing, you can now reduce the operation and transition of products by distributing products required nearby. This reduces transport time and lesser exhaust emissions and greenhouse emissions. Traditional manufacturing processes are known to emit huge waste, whereas 3D Printing or additive manufacturing only offers you what is needed, boosting the local economy.

Empowering Technological Innovation and Process

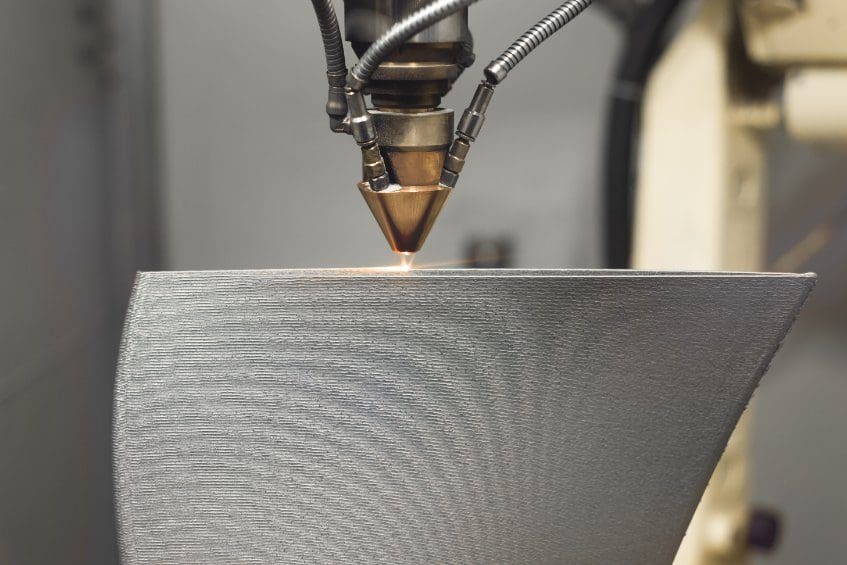

3D printing is known to support innovation by allowing rapid iteration of physical objects during R&D. It has paved the way for end-users, collaborators, and equipment manufacturers to connect efficiently from anywhere in the world and combine technology that would help in eradicating any kind of supply chain issue within the oil industry. With 3D printing, you can easily formulate complex designs, which would be difficult with the traditional manufacturing practices and methods. 3D printing also helps with the building of new layers of materials as well as encourages efficient operation of different aging parts and assets, and reduces the cost of equipment.

Helps with New Business Models

Some original equipment manufacturers have put AM technology to use to recapture the market from non-OEM sellers who sell in the ‘grey’ market products and equipment that are absent or hard to procure. What OEMs can do would be to send protected digital files to some trusted manufacturers who use 3D printing technology to produce the equipment and parts legally. It would reduce transportation costs, increase availability and reduce costs overall.

There are several challenges that are faced by industries when they incorporate 3D printing in their operations. One would have difficulty in part identification because not every part is suitable for AM, and the final outcome might not be as satisfactory as it would be with conventional methods. There are legal concerns as well, as AM could sometimes compromise safety standards.

For 3D printing, specialization is crucial, and this is a relatively new technology that is still undergoing research and is still in the development circle. However, along with the challenges, the benefits of incorporating 3D printing within the oil industry are manifold. With so many industries already making use of this technology, you can obtain any component within a jiffy with this.