The oil and gas industry has been a fundamental pillar of global energy production, delivering reliable and cost-effective energy to meet the increasing demands worldwide. The oil and gas sector, as revealed by the IMF’s 2020 data, represents approximately 1.7 percent of the global Gross Domestic Profit. Beyond its economic significance, this industry generates substantial tax revenue for governments worldwide. These funds play an indispensable role in financing essential public services and catalyzing infrastructure projects vital for societal progress and well-being.

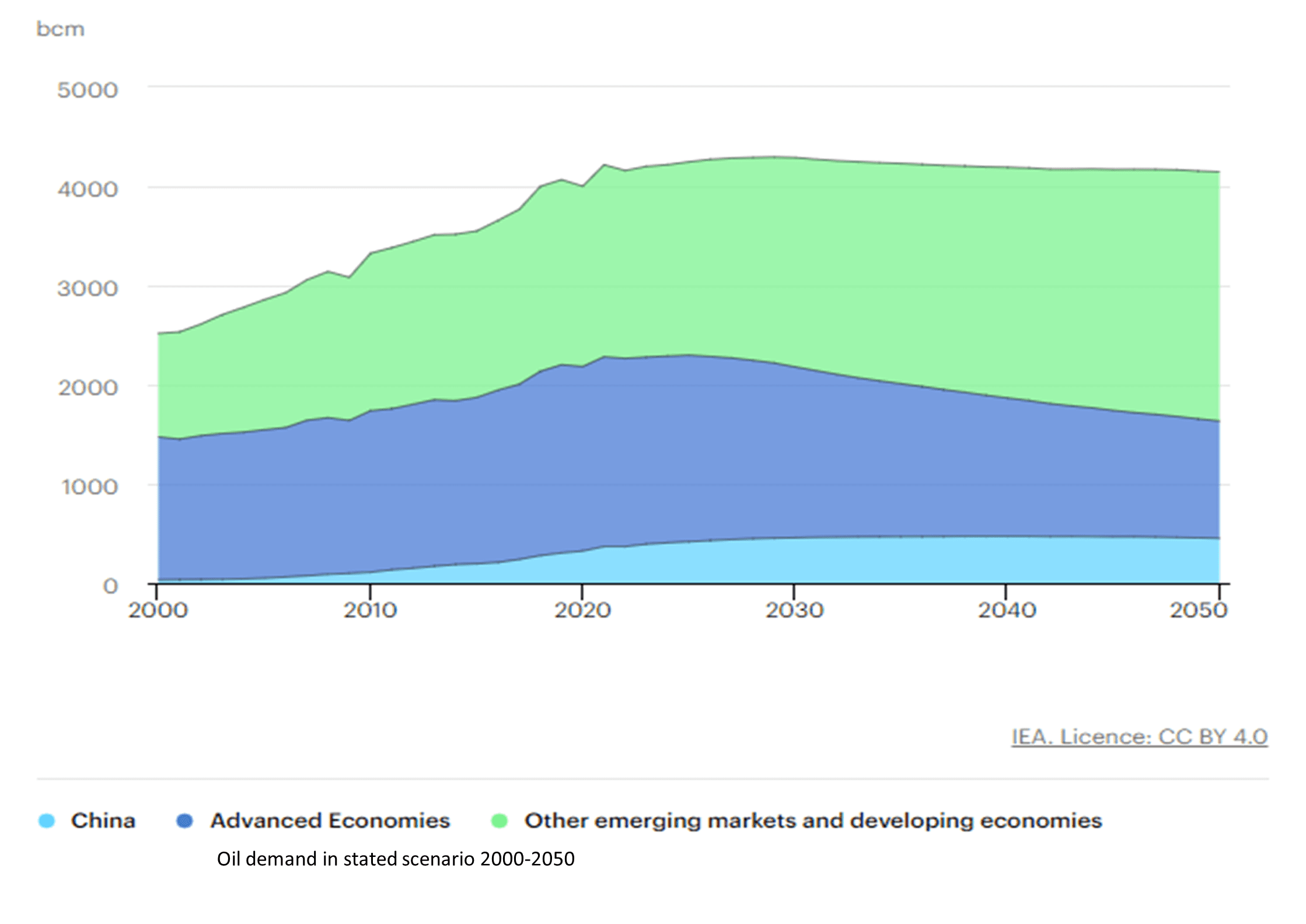

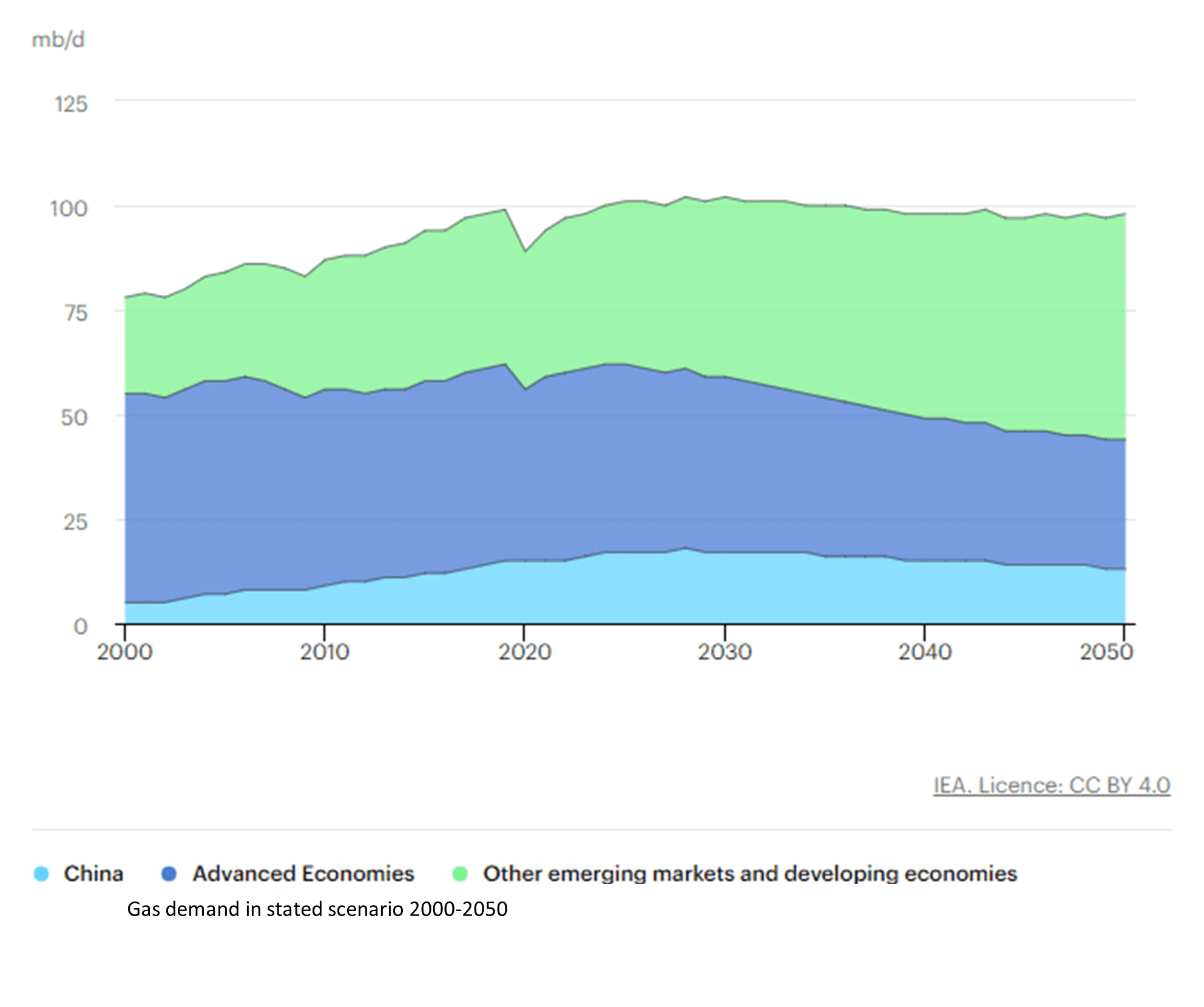

We can see the demand projection based on International Energy Agency (IEA) data for oil and gas below for 2000-2050. Today, oil and gas meet more than half of the global energy demand.

- Oil demand in stated scenario 2000-2050

- Gas demand in stated scenario 2000-2050

*Source IEA 2023 Energy Outlook.

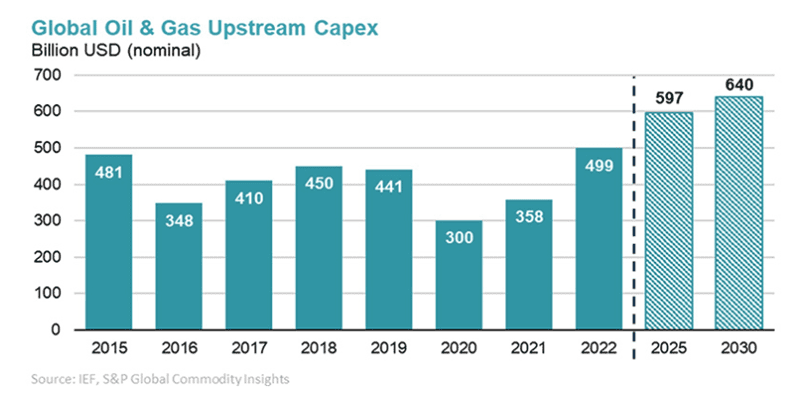

According to the International Energy Forum (IEF), capital expenditures in the oil and gas upstream sector saw a notable 39percent increase in 2022, reaching $499 billion. Projections indicate a further growth trajectory, with expenditures expected to rise to $640 billion by 2030 to ensure sufficient supplies. Estimates suggest that a staggering $4.9 trillion will be required between now and 2030 to meet market demands and forestall potential supply shortages, even in the event of slowed demand growth towards a plateau. Below, is a breakdown of the Capex investments in upstream oil and gas.

In the upstream energy industry, the significance of data acquisition and the adoption of new technologies cannot be overstated. These elements are crucial for various aspects including reservoir characterization, management, and production optimization. By leveraging data and technology, operators can enhance drilling operations, predictive maintenance, and asset integrity. This not only leads to cost reduction and operational efficiency but also ensures compliance with safety regulations.

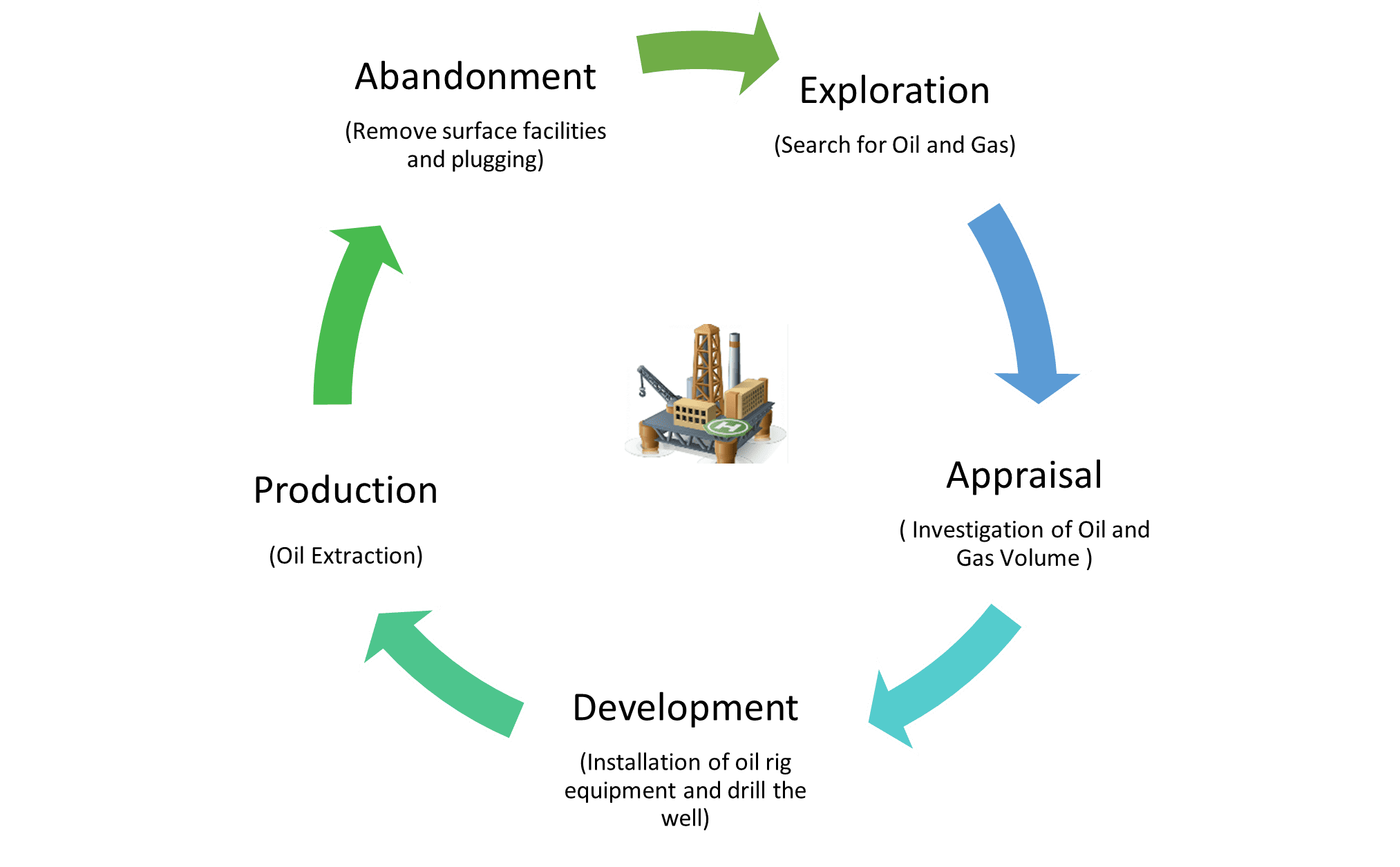

Before delving deeper into the analysis, it’s crucial to understand the intricate and costly nature of the drilling well cycle. Each phase of this process demands substantial investment, both in terms of finances and resources. For instance, the cost of drilling a single oil well in the Gulf of Mexico is estimated to be approximately $100 million USD. Such high costs underscore the industry’s commitment to leveraging advanced technologies and adhering to stringent safety and environmental standards throughout the drilling process.

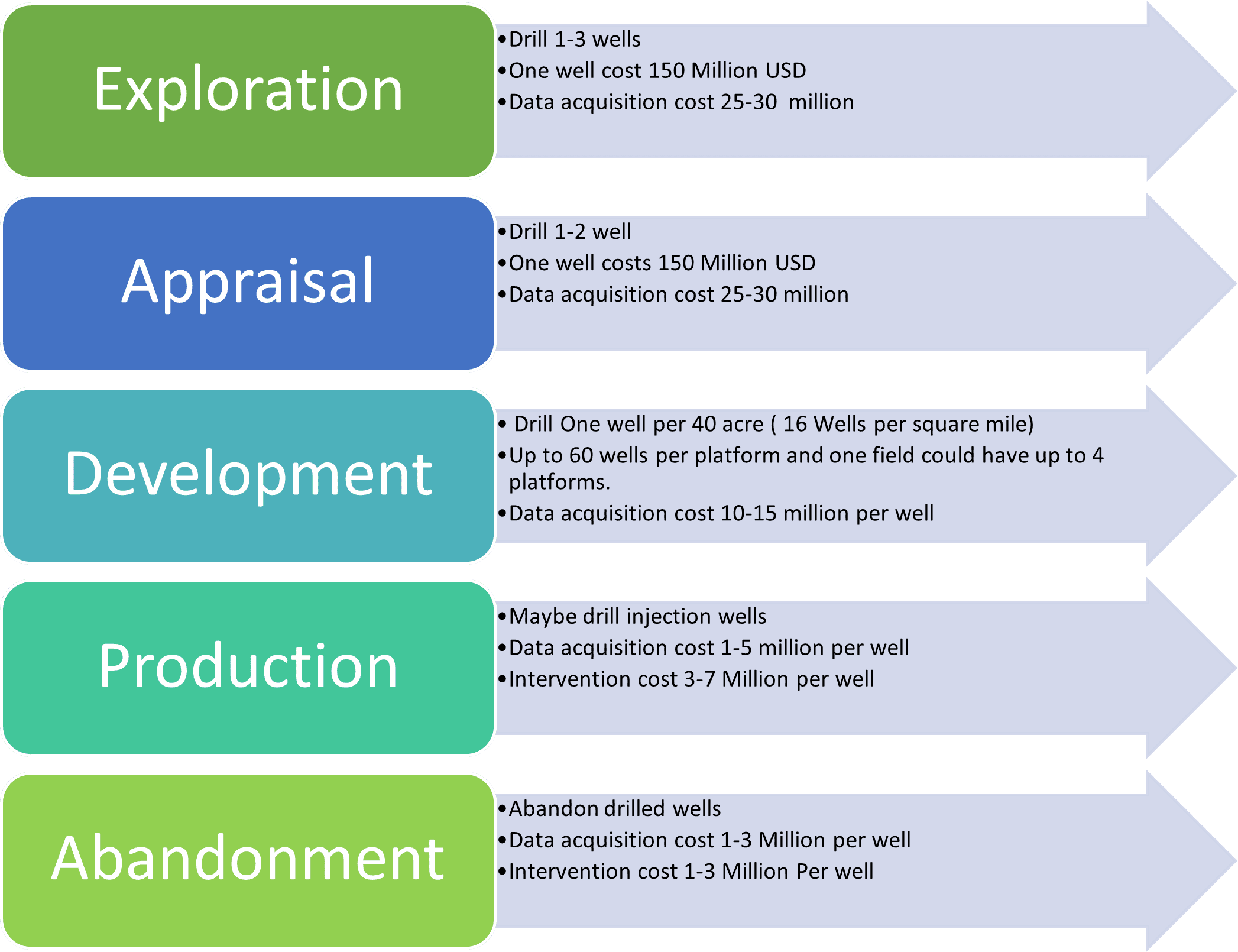

Here is the lifecycle of the oil well drilling process (source):

In the oil production process, acquiring comprehensive data is crucial for operational efficiency. Seismic data is initially gathered to locate ideal drilling spots, offering insights into subsurface structures. During drilling, wireline logs assess reservoir quality, aiding in productivity evaluation. In the development phase, multiple wells may be drilled, with data informing decisions on well placement and production optimization to maximize resource recovery.

In the oil production process, acquiring comprehensive data is crucial for operational efficiency. Seismic data is initially gathered to locate ideal drilling spots, offering insights into subsurface structures. During drilling, wireline logs assess reservoir quality, aiding in productivity evaluation. In the development phase, multiple wells may be drilled, with data informing decisions on well placement and production optimization to maximize resource recovery.

Data acquisition remains vital throughout production and abandonment phases. Continuous monitoring and diagnostic tests enable proactive maintenance and mitigate risks associated with well integrity and reservoir depletion. Throughout the oil production lifecycle, from exploration to abandonment, data acquisition supports informed decision-making and operational excellence.

In essence, data and technology are indispensable for the oil and gas upstream industry, driving innovation, efficiency, and sustainability across exploration, drilling, production, and asset management. Operators must adopt advancements to maximize resource recovery, minimize risks, and adapt to market dynamics. Data acquisition is the backbone, and embracing new tech fosters efficiency and innovation, enabling service companies to enhance technology in support of the industry’s needs.

Here are some advancements in the wireline logging and data acquisition:

- Digitalization and Sensor Technology / Advanced Logging tools and measurement techniques:

A monumental transition to digital sensors and cutting-edge technology systems have brought about a transformative revolution in data acquisition. These advanced sensors not only deliver unprecedented levels of resolution and accuracy but also empower more intricate measurements, providing a nuanced understanding of subsurface conditions. The integration of real-time data transmission goes beyond facilitating immediate analysis and decision-making; it stands as a pivotal force in reducing operational downtime and amplifying overall efficiency. Below are a few examples of the latest advancements:

- Dual flow line reservoir samplers are more efficient than single flow line reservoir samplers, reduce flaring, and are used to leverage automation in these samplers. As a result of the design of these samplers, deep transient testing can be done within a few hours, as opposed to days with a full-well test, which is a more time-consuming process.

- A multiline cable that can be used for both mechanical slickline and electrical lines. In addition to saving time when switching equipment for different cables, this can reduce space and increase efficiency.

- Geophysical surveys are essential to know the subsurface conditions and to determine favorable locations for mining and exploration. It takes a long time to record traditional seismic because multiple levels need to be recorded. However, with fiber optic seismic, you can capture seismic across the whole well in a matter of minutes, increasing efficiency considerably.

- Integration of Machine Learning and Artificial intelligence (AI) / Miniaturization and downhole automation:

The integration of machine learning, AI, and automation in reservoir management, drilling operations, and well monitoring optimizes strategies, enhances decision-making, minimizes intervention costs, and boosts operational efficiency in the oil and gas industry. These technologies enable predictive analytics in reservoir management, real-time optimization in drilling, and remote monitoring in well operations, driving overall performance improvement across the value chain. Here are a few examples:

- Several operators are using automation in drilling operations to improve safety and operational efficiency. By leveraging drilling systems equipped with real time data monitoring and control capabilities it is possible to achieve significant reduction in drilling time and operational costs. It also helps minimize human error and reduce exposure to hazardous drilling conditions enhancing safety.

- Artificial intelligence algorithms have helped optimize reservoir management and production operations. By analyzing vast amounts of reservoir data, including production rates, well performance and reservoir characteristics,it is imperative to identify opportunities for production optimization, performance enhancement and increased hydrocarbon recovery.

- Downhole automation technologies allow for real-time monitoring and control. By integrating downhole sensors with automated control systems, one can gain insights into downhole conditions in real-time allowing proactive drilling adjustments and optimized performance.

- Quantitative interpretation methods and Integration with geophysical imaging technologies:

There are several technology suites available today that help incorporate advanced quantitative interpretation methods for subsurface data analysis. This not only helps by integrating log data, seismic attributes, and reservoir simulation results, but also facilitates quantitative workflows that enhance reservoir understanding and decision making.

The oil and gas industry is essential for meeting global energy demands, particularly as alternative energy sources are explored. Drilling operations are pivotal in this context, with data acquisition serving as a crucial component throughout the well’s lifecycle, facilitating informed decision-making. Organizations must embrace new technologies to enhance operational efficiency and minimize hazards associated with human involvement, fostering innovation and resilience in a dynamic landscape.

Furthermore, oil and gas play a vital role in ensuring energy security amidst global uncertainties, providing reliable sources of energy that stabilize markets and mitigate supply disruptions. The adoption of new technologies not only improves operational efficiency and safety but also has the potential to reduce costs and increase profits. By optimizing processes and resource utilization, organizations can achieve significant cost savings and maintain competitiveness in the ever-evolving oil and gas industry.

Product and Service Delivery Manager Vishal Talreja is a standout performer in petroleum, drilling and logging engineering with a focus on leading all aspects of the development of offshore and onshore operations especially data acquisition, efficiency and sustainability, in support of the global oil and gas industry. Talreja holds a B.E. (Hons.) in Electronics and Instrumentation from the Birla Institute of Technology and Science in his native country, India.

He has played a major role in bringing a new oil and gas project to Larose, Gulf of Mexico, one of the top four drilling locations in the world. It is expected to come online later in 2024. His expertise in operations planning, resource management, service delivery and technology lifecycle management has ensured the Anchor-2 Well Project will be ready for it first oil production, estimated to exceed 440 million barrels, and meet the strict regulatory requirements. Anchor Field is located off the coast of Louisiana in some of the deepest water depths of approximately 5,000 feet.