While the current political shift has catalyzed a resurgence and new hope for the oil and gas industry’s future, green energy and decarbonization have remained of significant importance when steering the future’s energy demand to something sustainable and eco-friendly. To accomplish these goals, the major industry players are still looking for multiple viable solutions. Shell International Exploration and Production Inc. continues its commitment to clean energy with its recent announcement to sponsor Advanced Ionics’ development of a new class of green energy electrolyzers.

Advanced Ionics’ innovative technology concentrates on speeding up the decarbonization process and will be implemented through the Shell GameChanger program. The program was founded in 1996 and devised to pertner with businesses in the preliminary stages of developing ideas promising to impact the future of the energy industry. Support, technical expertise, and funding are all provided by the Shell GameChanger program while still allowing for independence in the decision-making process.

The oil and gas mogul will assess the water-vapor electrolyzer technology with the goal of producing low-cost hydrogen. If successful, Shell will portray the compatibility and justification to meet the company’s renewable hydrogen needs, and its ammonia production demands.

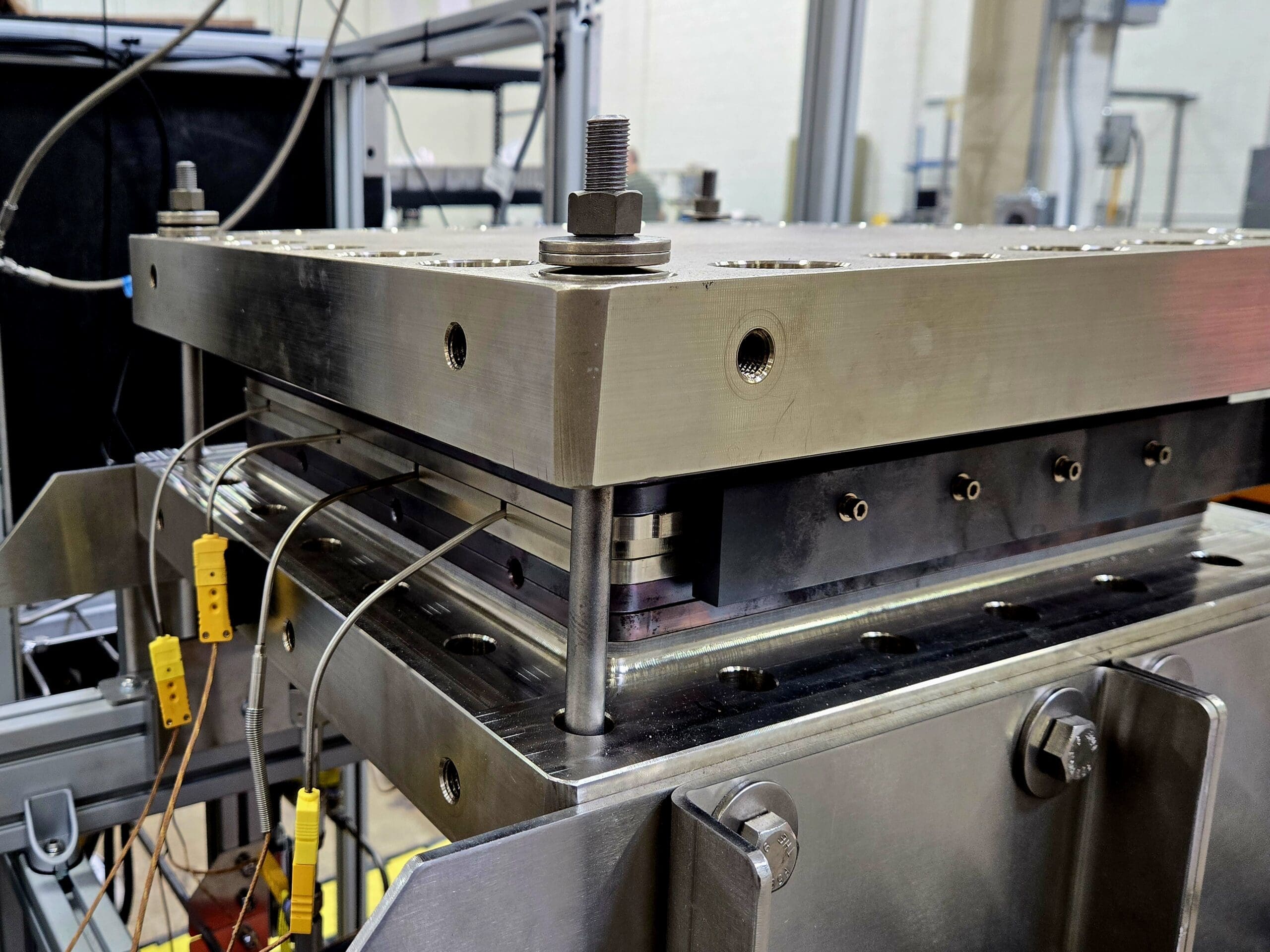

With a dependence on low-cost clean electricity, Advanced Ionics’ electrolyzer technology utilizes onsite processes or waste heat to produce green hydrogen for under a dollar per kilogram. By capturing that process or waste heat, Advanced Ionics possesses the ability to produce hydrogen for 35 kWh/kg, which touts a decrease in electricity per kilogram of produced hydrogen by 40 percent in comparison to alkaline and PEM technologies. Just like the current electrolyzing solutions that populate the current market, the Advanced Ionics technology carries decreased capital investments.

“The petrochemical industry will struggle to decarbonize without an economic path to producing and selling hydrogen and derivatives such as green ammonia,” said Advanced Ionics CEO, Chad Mason, in a recent press release. “Through our partnership with Shell GameChanger, we’re proving a new way to decrease the cost of green hydrogen through more efficient, symbiotic operations.”

Grand expectations are expected in the future. According to the International Renewable Energy Agency, today’s market share of global ammonia demand should quadruple by 2050. As a result, Advanced Ionics developed and implemented the Early Access Program to navigate the growing demand while meeting the needs of hydrogen producers and consumers across the oil and gas industry and others. Serving as an avenue for Shell to join the pilot project, the Early Access Program enables future consumers to evaluate and demonstrate the Advanced Ionics water-vapor electrolyzer for individual cases with specific operating parameters. This activity and exposure will allow for the scaling process to increase.

“We’re excited to support Advanced Ionics through the Shell GameChanger program,” said Shell GameChanger Principal, Ed Holgate, in the release. “Their innovative intermediate temperature technology, which utilizes available steam to reduce electricity consumption, promises to potentially enhance efficiency and sustainability in the petrochemical sector. Shell GameChanger is the perfect program to validate, de-risk, and nurture such groundbreaking solutions, providing the resources and expertise needed to bring them to market.”

Nick Vaccaro is a freelance writer and photographer. In addition to providing technical writing services, he is an HSE consultant in the oil and gas industry with twelve years of experience. Vaccaro also contributes to SHALE Oil and Gas Business Magazine, American Oil and Gas Investor, Oil and Gas Investor, Energies Magazine and Louisiana Sportsman Magazine. He has a BA in photojournalism from Loyola University and resides in the New Orleans area. Vaccaro can be reached at 985-966-0957 or nav@vaccarogroupllc.com.