Singapore – Oil and gas, chemical and shipping companies face the challenge of obtaining insight from an enormous amount of data to make better, more informed decisions. To enhance operations, improve productivity and workers’ safety and well-being, companies need to make sense of these data from the production facilities and connected products. By applying advanced analytics and artificial intelligence, companies in hazardous industries can identify trends and predict events through processes to quickly respond to disruptions, improve efficiencies, and even reduce risks of incidents.

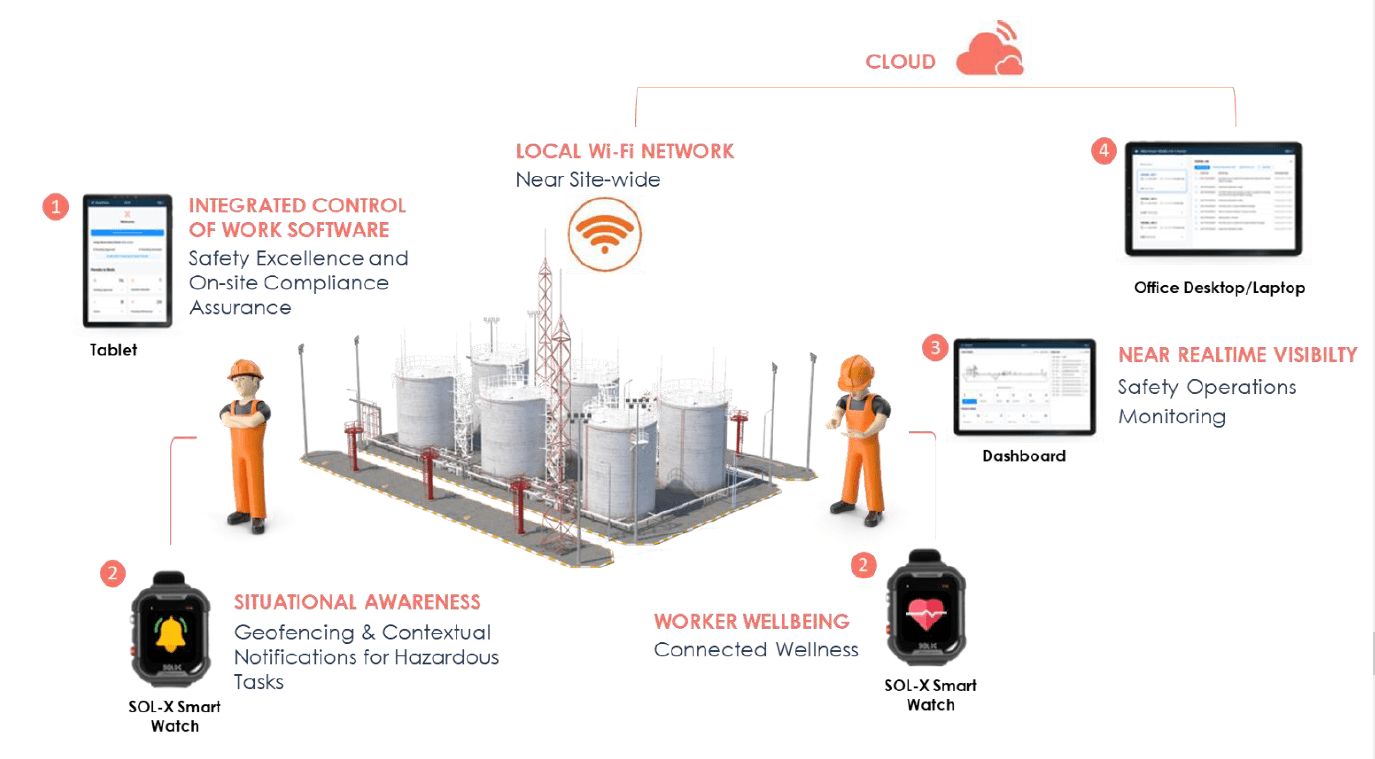

SOL-X’s solution, SAFEVUE.ai, addresses industrial safety through smart wearables and AI. It enables efficient and compliant Control Of Work and raises worker situational awareness and improves their well-being. Our integrated hardware and software solution are designed by our industrial safety experts to meet the unique requirements of high hazard environments. We aim to bring about a safer, more productive, and more sustainable world.

SAFEVUE.ai consists of two modules, Control Of Work and Crew Protect. These two modules have been enhanced and new features have been added to further improve worker safety at worksites. Improvements have been made to enhance our customers’ experience in using the Office Portal and creating Permits to Work with Smart Forms. Our reporting and analytics system produces leading indicators and insights for continuous improvement in terms of safety and compliance, operational efficiency, and well-being.

Download the attached media release to learn more.

Loading...

Loading...