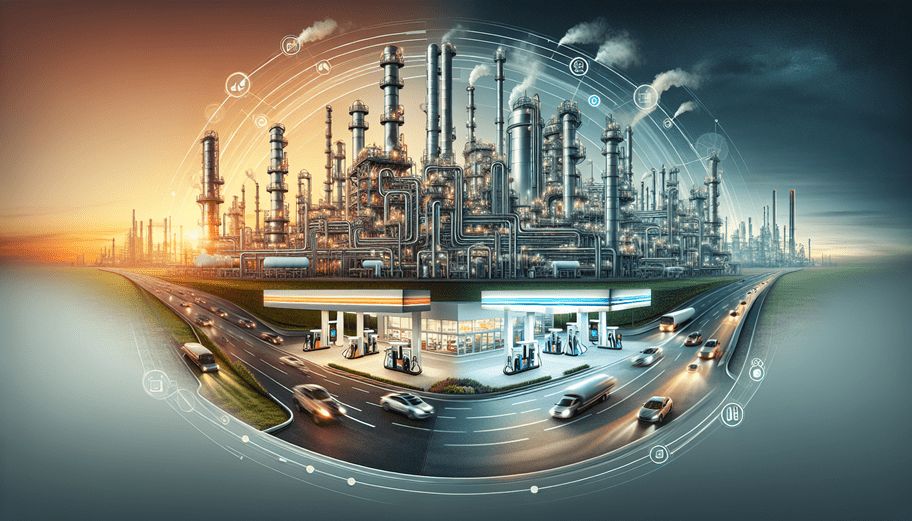

The downstream oil and gas sector plays a crucial role in transforming raw petroleum into everyday products that power modern life. From the refinery to the gas pump, this segment of the industry has a significant impact on global economies and consumer behavior. The downstream sector bridges the gap between crude oil extraction and the final products that reach consumers, making it an essential part of the energy value chain.

This article explores the key aspects of downstream oil and gas operations. It delves into the intricacies of the refining process, where crude oil becomes usable fuels and petrochemicals. The piece also examines the complex supply chain and logistics involved in moving products from refineries to consumers. Finally, it sheds light on marketing and retail strategies in the downstream sector, highlighting the differences between upstream and downstream activities in the oil and gas industry.

Overview of Oil Refining Technologies

The refining process plays a crucial role in transforming crude oil into valuable petroleum products. This complex procedure involves three fundamental steps: separation, conversion, and treatment. Refineries employ sophisticated technologies to break down crude oil into its various components, which are then selectively reconfigured into new products.

The process begins with separation, where crude oil is piped through hot furnaces and discharged into distillation units. These units separate the oil into fractions based on their boiling points, with heavier fractions settling at the bottom and lighter ones rising to the top. Modern refineries may utilize both atmospheric and vacuum distillation units to enhance the separation process.

Conversion is the next critical step, where heavy, lower-value distillation fractions are processed into lighter, higher-value products such as gasoline. The most widely used conversion method is cracking, which employs heat, pressure, catalysts, and sometimes hydrogen to break down heavy hydrocarbon molecules into lighter ones. Complex refineries may utilize various types of crackers, including fluid catalytic cracking units and hydrocracking units.

Key Refinery Output Products

Refineries produce a wide array of petroleum products that fuel modern life. The primary outputs include:

- Transportation fuels: Gasoline, diesel fuel, and jet fuel

- Heating fuels: Heating oil and liquefied petroleum gas

- Industrial products: Petrochemical feedstocks, lubricating oils, and asphalt

- Other products: Waxes and specialty chemicals

Interestingly, a U.S. 42-gallon barrel of crude oil yields about 45 gallons of petroleum products due to refinery processing gain, similar to how popcorn expands when popped.

Product Percentage of Total U.S. Petroleum Consumption (2016) Motor Gasoline 47% Distillate Fuel 20% Jet Fuel 8% Environmental Considerations in Refining

While essential for producing vital products, petroleum refineries face significant environmental challenges. They are major sources of hazardous and toxic air pollutants, including BTEX compounds (benzene, toluene, ethylbenzene, and xylene) and criteria air pollutants such as particulate matter, nitrogen oxides, and sulfur dioxide. These emissions can have serious health implications, potentially causing or exacerbating respiratory conditions and other health issues.

Water pollution is another concern, as refineries can contribute to groundwater and surface water contamination. Wastewater from various refining processes may contain oil residuals and hazardous wastes, requiring extensive treatment before release. Soil contamination, though less significant compared to air and water pollution, can occur from spills, leaks, or improper disposal of refinery waste products.

To address these environmental challenges, the refining industry is subject to numerous regulations, including the Clean Air Act, Clean Water Act, and Safe Drinking Water Act. Ongoing technological advancements and stricter enforcement of safety and environmental laws aim to mitigate the environmental impact of refining operations.

Supply Chain and Logistics in Downstream Operations

Transportation Methods for Refined Products

The downstream oil and gas sector relies on a complex network of transportation methods to move refined products from refineries to consumers. Pipelines play a crucial role in this process, with over 90% of crude oil and refined petroleum products transported by pipeline at some point. The United States has an extensive pipeline infrastructure, including over 200,000 miles for crude oil, refined products, and natural gas liquids.

Other transportation methods include:

- Rail: In 2017, approximately 140 million barrels of crude oil were transported by rail in the United States.

- Trucks: In 2013, trucks carried about 1.2 billion tons (roughly 380 billion gallons) of gasoline, diesel, and aviation fuel.

- Barges: Traditionally used for small amounts of crude oil transport, barge usage increased significantly with the development of the Bakken Shale in the early 2010s .

Storage Facilities and Distribution Networks

Storage facilities play a vital role in maintaining a steady supply of petroleum products. The natural gas industry utilizes nearly 400 underground storage facilities to ensure consistent supply during high-demand periods. Additionally, the federal government’s Strategic Petroleum Reserve can store over 700 million barrels of crude oil in underground salt caverns near Gulf Coast refineries.

Distribution networks are designed to efficiently move products from refineries to markets. Refineries are typically located near population centers to facilitate marketing and distribution of final products . The northeast U.S. has two federal oil reserves for use during brief supply disruptions, each holding a million barrels of home heating oil and gasoline .

Supply Chain Optimization Strategies

To optimize supply chain operations, oil and gas companies are implementing various strategies:

- Digital transformation: Deploying technology to gain increased visibility and accurately measure progress toward climate goals.

- Sustainability focus: Decreasing material waste, improving efficiency, and reducing carbon footprint.

- Talent management: Investing in retaining and reskilling the current workforce to address industry talent shortages.

- Transportation Management Systems (TMS): Implementing cloud-based software solutions for real-time tracking and issue resolution.

- Regulatory compliance: Working with oil and gas experts to optimize speed and compliance of supply chain processes.

- Strong industry relationships: Maintaining open communication channels with carriers, suppliers, and partners.

By implementing these strategies, companies can create more responsive, sustainable, and resilient supply chains, ultimately leading to improved customer satisfaction and increased profitability .

Marketing and Retail in the Downstream Sector

Branding and Product Differentiation

In the downstream oil and gas sector, branding and product differentiation play crucial roles in attracting customers. While gasoline from different refiners is often mixed at fuel depots, making it undifferentiable at the distributor level, retail companies employ various strategies to stand out. Many major oil companies invest heavily in branding efforts, with some spending over a hundred million dollars on branding initiatives since the Paris Agreement.

To differentiate themselves, companies focus on unique positioning strategies. For instance, Shell highlights its green accomplishments on its website, while TotalEnergies underwent a complete naming and identity rebrand to emphasize its commitment to sustainability . ExxonMobil, on the other hand, shares stories about its work in turning algae into biofuel, showcasing its innovative approach .

Retail Outlet Operations

Retail outlets are the face of downstream operations, where most consumers purchase their fuel. Companies often use additives to create brand-specific products. For example, Chevron brands its additive package as Techron. These unique formulations help companies differentiate their products at the pump, influencing consumer choices based on perceived quality or performance benefits.

Retail operations also involve managing fuel stations, convenience stores, and other associated services. Efficiency in these operations is crucial for maintaining profitability and customer satisfaction.

Digital Marketing in Oil and Gas Retail

Digital marketing has become increasingly important in the oil and gas retail sector. With the keywords “oil company” and “gas company” receiving up to 11,500 and 118,000 monthly searches respectively, having a strong online presence is essential. Companies utilize various digital marketing strategies, including:

- Search Engine Optimization (SEO): Optimizing websites to rank higher in search results for industry-related keywords.

- Pay-Per-Click (PPC) Advertising: Targeting users based on specific keywords or demographics.

- Email Marketing: Sending newsletters to keep customers informed about company news, promotions, and industry updates.

- Content Marketing: Creating high-quality, informative content to attract and engage potential customers.

- Mobile-Friendly Websites: Ensuring websites are optimized for the growing number of smartphone users worldwide.

By implementing these digital marketing strategies, oil and gas companies can improve their online visibility, engage with customers more effectively, and ultimately drive more business to their retail outlets.

Conclusion

The downstream oil and gas sector plays a crucial role in turning raw petroleum into everyday products that power modern life. From refining crude oil to distributing and selling finished products, this segment has a significant impact on global economies and consumer behavior. The complex processes involved, including refining, transportation, storage, and retail operations, showcase the industry’s commitment to efficiency and innovation to meet the ever-changing demands of the market.

Looking ahead, the downstream sector faces both challenges and opportunities. Environmental concerns and the shift towards renewable energy sources are pushing companies to adapt their operations and explore sustainable alternatives. At the same time, advancements in technology and digital marketing are opening up new avenues to improve efficiency and engage with customers. As the industry continues to evolve, its ability to balance traditional operations with forward-thinking strategies will be key to its long-term success and relevance in the global energy landscape.