Recently, I discussed the never-ending challenge of project communication with a friend, a professional who works in the oil and gas (O&G) industry. Our discussion got interesting … and quickly!

The Project Communication Challenge

Communicating detailed technical requirements can be complicated. Some industries and projects use the same phrases and terms to describe different things. Conversely, some use different phrases and terms to describe the same (or a similar) thing. Calling the same thing by different names or different things by the same name invites misunderstanding.

I said: when a glossary is implemented as a single authority or source of truth for a project significant benefits are realized.

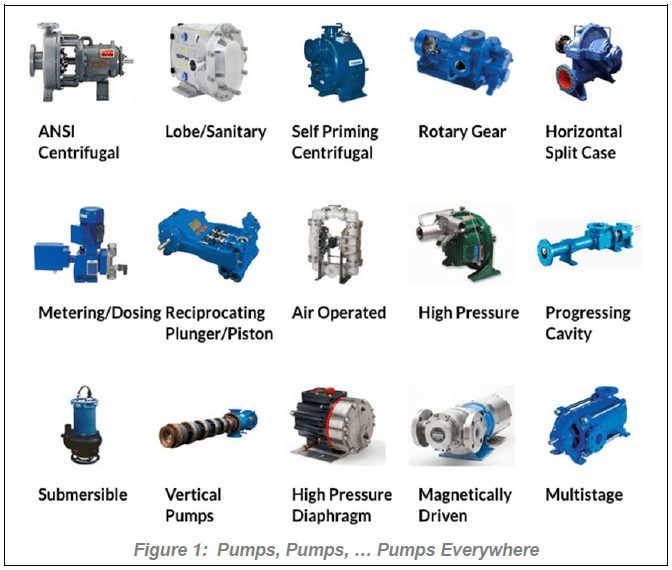

He was not convinced. How could such a remarkably simple solution, a glossary, have a significant impact on project success? He asked: isn’t a pump – a pump – a pump? What’s the problem here? What he meant by this was: how could this be confusing? Pumps are essentially the same and can be treated the same when being procured. What could be so confusing about this?

On the surface his statement made sense. However, in practice, defining requirements for pumps can get very complicated. This is a good example of ineffective project communication. Figure 1 illustrates 15 types of pumps supplied by one company.

On the surface his statement made sense. However, in practice, defining requirements for pumps can get very complicated. This is a good example of ineffective project communication. Figure 1 illustrates 15 types of pumps supplied by one company.

Miscommunication occurs when requirements are unclear or understanding is not confirmed by stakeholders. Yet, everyone thinks that their understanding is clearly the correct understanding, which is assumed to be self‑evident – so why would it need to be confirmed or explained? This problem of lack of clarity is hidden in plain sight!

The Background

It is widely accepted that project teams struggle with communication. The Project Management Institute estimated that ineffective communication puts 7.5% of a project’s budget at risk[1]. The all-to-frequent outcome is that equipment is delivered incomplete, incorrect, or late.

This challenge costs projects millions of dollars in delays, rework, and waste. Hence, the iron law of (mega)projects is: over budget, over time, over and over again!

The causes of ineffective communication are well-known. At the top of the list is a lack of common understanding of key concepts and terminology essential for project success. The Construction Industry Institute reported that industry lacks a common language, and each company uses its own terminology[2]. This is as true today as it was in 2014!

Miscommunication and misunderstanding permeate project communications between and within engineering and procurement (EP), owner, supplier, and other stakeholder teams. Avoiding costly and undesirable outcomes requires that the root causes be addressed.

Pumps and Quality Plans

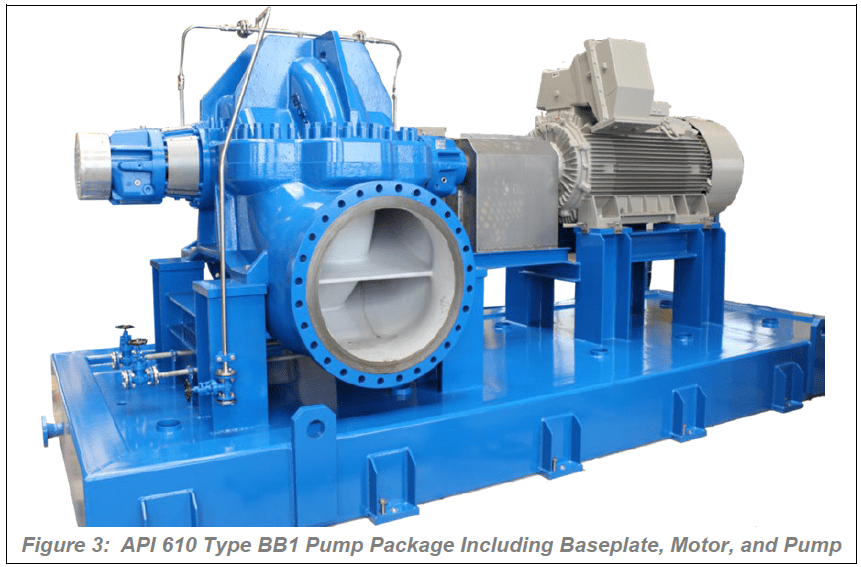

There are many types of pumps. When a pump is purchased by a project, the responsible engineer (RE) – often a mechanical engineer – specifies its requirements in the purchase order (PO):

- The pump type in the data sheet by name. The data sheet is one of the procurement documents used to procure equipment for a project;

- Pump requirements. These may include appurtenances, configuration, instrumentation, materials, seals, and testing; and,

- Other details. This may include auxiliary equipment or sub-assemblies such as a baseplate, coupling, lubrication oil system (LOS), and motor.

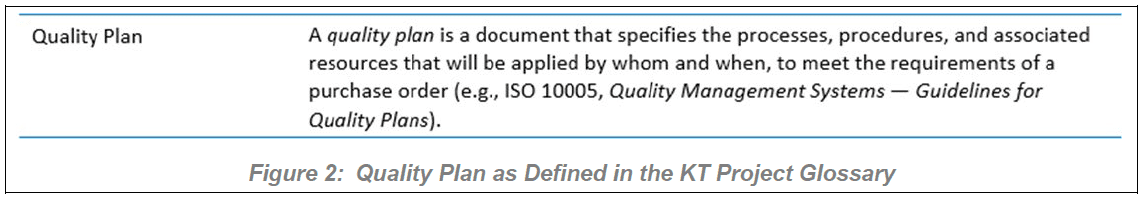

A better example of how miscommunication and misunderstanding starts is when the RE specifies that the pump supplier shall submit a specific document – a quality plan – for review and record (see Figure 2). This may be an item on a checklist or drop-down menu. Or it may be something that was required by another project that the RE had experienced.

Is a quality plan a useful document? With it, could a higher quality product be produced? It seems logical to use a quality plan when producing a pump. The problem is that there is no universally-accepted definition of quality plan; the more people you ask, the more varied and differing definitions you will get. This is the root of the problem. What, really, is a quality plan? And does a project really need one?

Is a quality plan a useful document? With it, could a higher quality product be produced? It seems logical to use a quality plan when producing a pump. The problem is that there is no universally-accepted definition of quality plan; the more people you ask, the more varied and differing definitions you will get. This is the root of the problem. What, really, is a quality plan? And does a project really need one?

A quality plan can easily be confused with these 15 related items:

- Construction travel sheet;

- Inspection and test plan (ITP);

- Inspection and test requirements;

- Inspection plan;

- Quality check list;

- Quality control manual;

- Quality control travel sheet;

- Quality control traveler;

- Quality management requirements;

- Quality management system manual;

- Quality surveillance plan;

- Quality verification points (QVPs)

- Shop traveler; or,

- Surveillance plan

- Witness and hold points.

The obvious solution is for the RE to define what shall comprise the quality plan (e.g., a technical note in the data sheet or material requisition, if the pump specification does not include a definition). There! Problem solved. But wait … not so fast.

REs are busy professionals. They do not have time to write detailed notes explaining the exact composition of every deliverable. Besides, is it not the pump supplier’s responsibility to know what a pump quality plan is and what information to include within it?

Unfortunately, there are several more steps to take (or communication stumbling blocks to overcome) before a suitable quality plan can be created, delivered, and implemented. These steps involve communicating detailed requirements for the deliverables (i.e., documentation and equipment) through the supply chain. Later, this involves the production and issuance or shipment of deliverables to the project.

In addition to a quality plan, the PO may also require an ITP. This is a document with similar content to a quality plan but that is produced for a very different purpose. An ITP is a quality control (QC) document; the quality plan is a quality assurance (QA) document. It is a common oversight for project personnel to assume that the ITP is the quality plan or vice versa. This understanding is usually not explained in the PO nor confirmed by the responsible personnel – before it is assumed as not required because it is a duplication or produced incorrectly (e.g., one document in either format is produced to meet both requirements).

Adding to the complexity, projects require dozens or even hundreds of pumps, often of many varieties. Pumps that are the same or similar can be purchased together, using the same supplier to save money and time. Still, a project may have numerous POs for various pump types.

Figure 3 depicts a typical pump package with a baseplate, motor, and pump. As shown, this package does not have a LOS. The figure caption is written by the pump’s original equipment manufacturer (OEM) – Delta-p. The horizontal spilt case pump shown in Figure 1, manufactured by pump OEM Pump Engineering Company, is the same type of pump! This is a classic example of how two different phrases describe the same thing: the horizontal split case pump in Figure 1 and the Type B1 pump package in Figure 3 are the same thing. While terminology may vary, the product does not!

Tis Confusion!

Tis Confusion!

It gets far more complicated – and confusing.

So, who is the pump supplier? This may be the OEM for the pump, or another business such as a distributor or fabricator that packages the pump. Therefore, they are referred to as the prime supplier. The prime supplier is responsible for all aspects of the design and production of the pump assembly including each sub‑assembly, whether it is supplied directly or indirectly.

Packaging refers the need for the prime supplier to design and procure or produce the assembly and sub‑assemblies that comprise the pump system. The pump is then delivered as a turnkey asset to the project, to be installed and commissioned, and then operated by the owner.

A sub‑supplier supplies equipment or materials to the prime supplier through a supply chain. For example, a sub-supplier could be the OEM that supplies the motor that powers the pump. Other sub-suppliers could be the baseplate and LOS fabricators. Lastly, a sub-sub-supplier could be a coating applicator that paints the baseplate for the baseplate fabricator.

Many projects require quality plans from their suppliers. This is not new. This requirement, however, does not explain the actual project-specific requirements that comprise the quality plan. In summary, these parties are often included in the procurement of a pump but may have vastly different understandings of what comprises a quality plan, or if it is even needed, without a single authority (i.e., a glossary definition):

- Project owner, including project personnel.

Responsible for: providing owner specifications and identifying project documentation requirements.

- EP company, including discipline engineers and REs.

Responsible for: preparing data sheets and specifying document deliverables in the PO, including a quality plan, if required.

- Prime supplier (e.g., pump distributor, OEM, or packager), including sales, production, and technical personnel.

Responsible for: issuing document deliverables per PO, including a quality plan, if required (per quality management system, standards, and work procedures).

- Sub-supplier (e.g., baseplate, LOS, and motor), including sales, production, and technical personnel.

Responsible for: issuing document deliverables per PO, including quality plan, if required (per quality management system, standards, and work procedures).

- Sub-sub-supplier (e.g., baseplate coating applicator), including sales, production, and technical personnel.

Responsible for: issuing document deliverables per PO, including quality plan, if required (per quality management system, standards, and work procedures).

The procurement documents will also include a motor data sheet, which may be prepared by another discipline engineer (i.e., an electrical engineer). Does the motor also need a quality plan? Does the electrical engineer need to write detailed notes explaining the exact composition of a quality plan? Should it be different than the pump quality plan? Is a quality plan required for the LOS or any other sub-assembly? Who knows?

Adding to the complexity is that pump suppliers supply pumps to multiple industries – not just O&G. At any time, suppliers may produce pumps for military, municipal water, power, pulp and paper, or other industries. Suppliers have a plethora of quality plans from past projects that are readily re-purposed for new projects.

Without any defined requirements for a quality plan, most suppliers will produce a quality plan that they understand to be appropriate. However, this understanding is usually incorrect. Thus, first draft quality plans frequently do not fulfill project requirements. This is common in the O&G industry because quality plans must be project-specific and cannot be generic or standardized to be useful. Unfortunately, there are no industry- or regulatory‑mandated requirements for quality plans, nor can there be. And hence, confusion persists.

An Analogy – Purchasing Cake and Cookies at a Bakery

Cakes and Specialized Equipment

Think of the last time you purchased a cake at a bakery. Do you tell the baker what kind of cake you wanted or did you order the same cake the last customer ordered? Surely, the former because the last customer likely had different cake requirements than you. To order the cake, you specify a type (e.g., chocolate, tiramisu, or vanilla). Should it be gluten-free or low-sugar? What color of icing should it have? Should it have decorations, writing, or a combination? Does it need candles? If yes, how many? Is it for an anniversary, birthday, wake, or something else? How big should it be?

Much in the same way a baker is incapable of making the cake correctly without knowing the cake’s ingredients and presentation requirements, a supplier cannot successfully supply a pump package without knowing the necessary pump components and features. A cake is a supplier’s custom-designed equipment.

Cookies and Standard Equipment

Think of the last time you purchased cookies at a bakery. A bakery may regularly produce standard chocolate chip cookies. Chocolate chip cookies are inexpensive, popular, and tasty. Most customers purchase them for these reasons. A chocolate chip cookie is a supplier’s cookie-cutter or off‑the‑shelf pump design. Like a chocolate chip cookie, the design inexpensive and popular. Everyone is familiar with the product, the product is accessible, and no special instructions need to be relayed to acquire it.

The Next Steps Are Straightforward, But …

After the PO is issued to the prime supplier, the project’s cost and delivery schedule are locked in. In sequence and quickly, the prime supplier issues POs to their sub-suppliers and begins preparing engineering deliverables such as drawings and the quality plan.

Then, the engineering deliverables are submitted to the EP company as required by the PO. For example, the quality plan is submitted for review within four weeks of the PO being issued. When the quality plan is received by the RE, however, then the problem suddenly becomes apparent. The quality plan received is not what was expected. It is in the incorrect format, missing crucial data, and cannot be used. Oops! Again.

Without a project-specific definition of a quality plan, each organization and its personnel may assume that their understanding of the quality plan is correct. This inevitably causes problems when the quality plan is issued to the RE. Then, this requires clarification emails or meetings and rework to re-write and re-issue the quality plan. All these expensive machinations contribute to project going over budget, over schedule, or both.

Ineffective Project Communication

Late problem identification is a great example of the consequences of ineffective project communication. This occurs when the quality plan received does not comprise what the RE or another stakeholder (e.g., the owner) expects and requires.

The quality plan could:

- Be missing information about the sub‑suppliers and sub-sub suppliers’ responsibilities and scopes;

- Instead be an ITP and not a quality plan at all;

- May not include any separate sub-supplier or sub-sub-supplier quality plans; or,

- Not comply with quality plan requirements per ISO 10005, Quality Management Systems—Guidelines for Quality Plans.

Why were quality plan requirements not defined in the procurement documents? The consequences of this failed communication are additional costs and time delays that would not be necessary at all if the project had defined quality plan in the first place.

Because of this miscommunication and misunderstanding, the quality plan may be:

- Accepted as-is or with minor changes, even though it does not fully meet the RE or other stakeholder’s expectations or requirements). This may introduce unwanted risk; or,

- Revised and resubmitted (with a schedule delay, which may or may not delay production). If the newly defined requirements:

- Exceed industry or supplier standards, the supplier may dispute the need or seek clarification of requirements, which will further delay the schedule; or,

- Are deemed out-of-scope from the PO (i.e., not considered in the original bid), then additional payment may be requested. This also requires the provision of additional procurement documents and a PO revision, which will further delay the schedule and increase costs associated with additional EP labour hours to produce the PO revision.

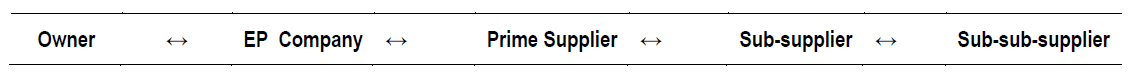

Conventional project hierarchy dictates that formal project communication flows as shown next.

A communication or clarification (e.g., regarding the definition or explanation of the phrase quality plan) could be emailed to some or all recipients. The communication cannot, however, override existing commercial agreements (i.e., POs) and contractual reporting structures.

A communication or clarification (e.g., regarding the definition or explanation of the phrase quality plan) could be emailed to some or all recipients. The communication cannot, however, override existing commercial agreements (i.e., POs) and contractual reporting structures.

More communication therefore takes more time. And time, as everyone knows, is money.

It Only Gets Worse

Recall that a project may have several POs for pumps. Each PO may not have a clear definition of quality plan. This complexity worsens the problem exponentially with pumps and all other equipment.

For instance, projects have many other POs for engineered and packaged equipment for which a quality plan may be required (e.g., control cabinets, control valves, electrical houses, instrumentation packages, modules, motor control centers, pressure equipment, and switchgear). If each of these POs also lack a clear definition of quality plan, the problem of additional costs and time that would not be necessary is multiplied – again.

Thus, failing to clearly define quality plan at the outset of a project results in:

- Decreased personnel and stakeholder satisfaction;

- Equipment delivered incomplete, incorrect, late, or not at all;

- Miscommunication, especially with new personnel;

- Increased costs because additional labor is required to revise POs; and,

- Increased costs to pay for the unexpected increase in the scope of supply.

Given the above, imagine the burden that ineffective communication has on a project tasked with producing dozens or hundreds of POs, and processing hundreds of thousands of procurement and supplier documents. And the phrase quality plan is only one phrase! A project typically uses dozens or hundreds of project terms and phrases that need clear definitions. How are project personnel expected to communicate effectively without a single authority that clearly defines the terminology used by all project personnel? It is a great question.

As a result of ineffective communication, it is easy to see why the iron rule of (mega)projects is so pervasive: over budget, over time, over and over again! Similarly, it is easy to see how ineffective communication puts 7.5% of a project’s budget at risk.

It is unreasonable to expect all personnel to have the same understanding of industry and project definitions. And yet, this assumption is routinely made when terms are not defined or understanding is not confirmed.

Ambiguous terminology frustrates project success. Industry- and project-specific terminology is especially challenging for personnel who:

- Have experience, but need to confirm mutual understanding;

- Have transferred into a new company, industry, project, or role; or,

- Use English as a second language (ESL).

Spoiler Alert!

It is the ITP, not the quality plan that is key to ensuring inspection and testing requirements are complete and correct.

Most projects do not need or use a quality plan; it is a rarity with O&G projects. What is always required is an ITP, which can be provided for any assembly or sub-assembly and by any supplier or sub-supplier. These terms, however, may be used interchangeably!

The ITP is a quality control document used to control and record all inspection and testing requirements relevant to a PO. It identifies the QVPs that require inspection. For example, this may include the review of a non-destructive examination (NDE) test reports (e.g., a radiographic or ultrasonic tests of welds) or the witness of a pump performance test. An ITP identifies the personnel responsible for acceptance, and references the acceptance criterion and specifications.

The quality plan is a quality assurance document that specifies the procedures, processes, and resources that will be applied by whom and when, to meet the requirements of a PO. For example, it explains the supply chain, and identifies sub-supplier and sub-sub-supplier roles and responsibilities. This is a high-level document that does not identify QVPs with acceptance criterion and specifications, or the parties responsible for acceptance.

For an O&G project a quality plan may only be used for the most costly and complex packaged equipment, such as e-houses, equipment modules, or water treatment packages.

This is invaluable key knowledge for project personnel (e.g., EP, owner, or supplier teams). If something is not required – do not request it. If something is required, ensure that it is properly communicated and defined. Use this simple method to avoid frustration and wasting money and time.

The Solution to the Challenge

The meanings of terminology used by each stakeholder may vary, sometimes to the point of confusion and misunderstanding. This is the nature of industry- and project-specific terminology, and this challenge must be addressed. If it is not, a project faces unknown risk. Ultimately, the goal is to provide an ever more efficient process to drive future project success. To accomplish this, a project (i.e., in the procurement documents) must define terminology and foster a common understanding of that terminology from all project personnel. But how?

To be clear, project communication must have a single authority for company, industry, and project terminology. To be effective, project communication must flow from the owner and the EP company to the prime suppliers, and from them to the sub-suppliers and sub-sub-suppliers, and vice-versa.

A modern, up-to-date, and well-written glossary provides precise definitions for phrases and terms, including:

- Abbreviations and acronyms;

- Brand names, proprietary names, and trademarks;

- Company-, discipline-, industry-, and project-specific terminology;

- Expressions, historical use of terms, etymology, and social influencers of jargon and slang;

- Phrases and terms used by third parties; and,

- Preferred and non-preferred terminology.

Implementing a glossary has major benefits, including:

- Accelerated capital projects (assets delivered better and faster);

- Enhanced project communication;

- Improved project performance (on-budget and on-time);

- Improved personnel on-boarding, team morale, and stakeholder satisfaction;

- Reduced frustration and rework; and,

- Significant cost savings (e.g., 7.5% of a project budget).

To maximize glossary benefits for any project, implement these steps:

- Prepare a glossary as the definitive single authority for company, industry, and project terminology;

- Deploy and maintain the glossary as the source of authorized terminology;

- Integrate authorized terminology into all business, project, and strategic documents;

- Train personnel about the proper use of the glossary; and,

- Update the glossary on a regular basis, especially as meanings of terminology change and as new terminology is used.

The KT Project Glossary

Many companies have difficulty creating and maintaining their own glossaries. This is a time-intensive task that requires knowledgeable resources. Further, most are not qualified, do not have the mandate or the time, or are otherwise too engaged elsewhere to spend effort writing a glossary. Sometimes it is easier and more cost‑effective to acquire than create.

The KT Project Glossary of Common Industry and Project Terminology (KT Project Glossary) is a brilliant and industry-leading document developed over years of research, writing, and editing. It provides precise definitions for new and conventional terminology that greatly reduce the risk of miscommunication and misunderstanding for projects. It is a:

- Compendium of business, career, engineering, industry, procurement, project, and scientific terminology comprising about 200,000 words and 550 pages. It contains up-to-date, relevant terminology and over 1,600 real-world examples.

- Guideline prepared for use specifically with capital projects in energy industries. It is also relevant and useful for capital projects in other industries (e.g., mining, petrochemical, and power) and sectors (e.g., associations, construction, and manufacturing).

Contact the KT Project today to learn how the KT Project Glossary can address your project challenges.

Additional Resources

The KT Project helps capital projects in the energy and other industries by implementing best practices for knowledge transfer and project communication. Visit the KT Project website at: http://www.ktproject.ca for more information.

To learn more about effective communication and project success, read these KT Project ebooks:

- Successful Projects Need Effective Communication – Tackling a complex challenge with a simple solution

- The Key to Project Success – It’s All In How You Start!

Figures

- Pumps, Pumps, … Pumps Everywhere, Pump Engineering Company, http://www.pumpengineering.net/blog/industrial-pump-types-benefits-application/

- Quality Plan as Defined in the KT Project Glossary, KT Project, www.ktproject.ca

- API 610 Type BB1 Pump Package Including a Baseplate, Motor, and Pump, Delta-p, Pumpe og Kompressorsystemer AS, https://www.delta-p.no/products/api-610-pumps/bb1/

- Packaged Equipment Defined, KT Project, www.ktproject.ca

References

- Project Management Institute, The High Cost of Low Performance: The Essential Role of Communication, https://www.pmi.org/-/media/pmi/documents/public/pdf/learning/thought-leadership/pulse/the-essential-role-of-communications.pdf

- Construction Industry Institute, Achieving Zero Rework Through Effective Supplier Quality Practices – RS-308-1 Research Summary, https://www.construction-institute.org/resources/knowledgebase/best-practices/materials-management/topics/rt-308

Roy O. Christensen is a Welding Engineering Technologist who has over 35 years’ experience with oil and gas, pipelines, and other projects. He has authored countless instructions, manuals, plans, proposals, reports, specifications, and other documents that continue to drive success for many projects. He is the founder of the KT Project, which saves organizations significant money and time, by providing key resources to leverage expert knowledge transfer for successful project execution.