All oil and gas companies operate under the motto “safety first,” i.e., ensuring zero injuries to personnel, zero work-related accidents, and zero environmental incidents. In today’s industry, the push for safer, more efficient, and environmentally responsible operations is stronger than ever. Over the last decade, one area that has made significant strides is the elimination of the radioactive source from the drilling bottomhole assembly (BHA). The removal of the radioactive source from the BHA not only improves the HSE aspects of the operation but also improves well efficiency while reducing operational complexity and simplifying dealings with regulatory bodies in case of a stuck pipe or lost-in-hole (LIH) incidents.

The Legacy of Radioactive Logging

Measuring formation density and neutron porosity is a critical part of the formation evaluation process. Traditionally, these measurements have mandated the use of high activity radioactive sources in the drilling BHA. While the utilization of the radioactive source provides reliable and accurate data, it comes with the additional operational, regulatory and environmental challenges.

Handling radioactive sources requires following strict safety guidelines to avoid overexposure, which can cause serious health concerns. These sources are transferred to and from the wellsite in specialized containers under the supervision of certified and trained personnel. Storing these sources at the operational bases requires following the protocols defined by the regulatory bodies. In the event that a BHA with the radioactive source becomes stuck or lost in a hole – a risk that has increased with high-angle wells, 3D trajectories and long laterals – operators need to consult with the concerned regulatory body and follow rigorous and time-consuming recovery or abandonment procedures. In some cases, this can lead to the loss of recoverable hydrocarbons and to the complexity of long-term monitoring of wells with lost radioactive sources.

Figure: Radioactive source loaded inside an LWD tool (Source: SPE SPE-175179-MS)

The High-Angle Drilling Challenge

With the objective of increasing hydrocarbon recovery by maximizing reservoir contact, the number of high-angle and horizontal wells drilled has increased significantly. With advances in geosteering technologies, these wells have seen higher productivity and boosted recovery, while also carrying their own operational risks. Issues such as hole cleaning, increased torque and drag, and differential sticking increase the likelihood that the BHA will become stuck in these well profiles. The presence of radioactive sources in these situations amplifies the problems by complicating recovery operations and introducing complex abandonment procedures if the BHA cannot be retrieved.

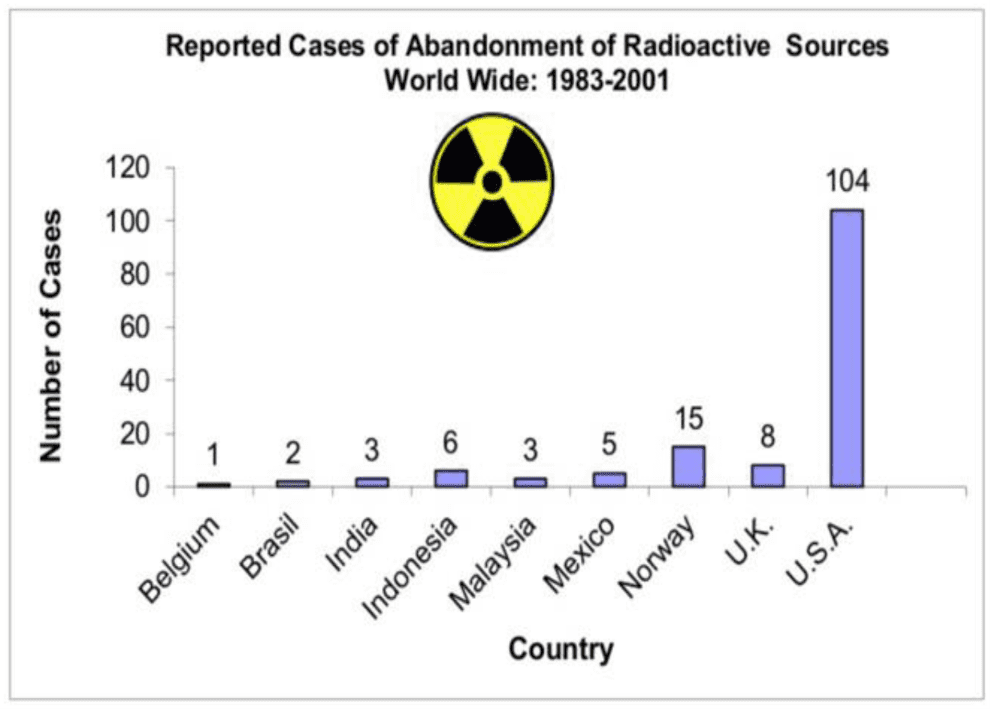

Studies have shown that the probability of losing a BHA downhole increases with the complex well geometry. Consequently, eliminating hazardous materials from the drilling BHA in these complex wells has become imperative for many operators to mitigate risks and streamline operations.

Figure: Reported cases of abandoned radioactive sources worldwide (Source: SPE 181279-MS)

The emergence of new technology

Over the past decade, a new generation of technology with advanced sensors and detectors has emerged, providing similar subsurface measurements without the need for a radioactive source. This innovation effectively removes one of the most hazardous components from the BHA, while maintaining similar formation evaluation data quality that Petrophysicists and Reservoir Engineers rely on. The technology provides high-quality formation evaluation data in real time, helping operators understand reservoir properties, optimize well placement, and maximize hydrocarbon recovery. The technologies have matured over time, with improved measurement accuracy, and are now used reliably in a variety of challenging drilling conditions, such as high-angle and extended-reach wells.

Proven Benefits in the Field

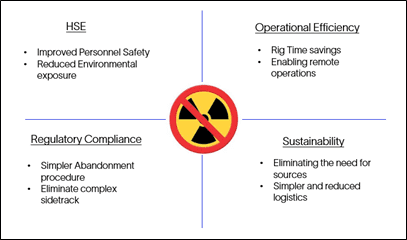

The technologies have evolved and demonstrated robust performance under tough conditions, eliminating the need for radioactive sources and proving their significant advantages:

- Improved HSE aspects: Eliminating the risk of radiation exposure to the field personnel

- Enhanced Operational Efficiency: Eliminating the need for loading and unloading the radioactive source in the drilling BHA

- Simplified regulatory compliance: Eliminating the complex abandonment and sidetrack procedure for a stuck or lost-in-hole BHA

- Enable Remote Operations: Removing the need for having the radiation certified personnel at the wellsite

Figure: Benefits of eliminating radioactive sources

A Strategic Adoption Framework

The handling and use of radioactive sources in many locations require extensive licensing and monitoring from the local and international regulatory bodies. Often, this significantly increases operational costs and delays operations. Removing the use of radioactive sources reduces operational complexity for both operators and service companies.

Recognizing the potential of these new logging technologies, companies have developed a new workflow to guide their deployment, ensuring that the technology is used in situations that offer maximum value:

- High-Risk Wells: Eliminating the use of radioactive sources in wells that have a higher probability of stuck pipe or lost in hole, so as to reduce the financial burden of fishing or complex abandonment operations.

- Environmentally Sensitive Areas: Wells in the ecologically sensitive zones or with high population density, removing hazardous radioactive material enhances safety

- Development Wells: Development and production wells in the field where subsurface formation data is well understood

- Remote Fields: Field locations where transportation and handling of radioactive materials are a significant challenge, sourceless technologies offer a much simpler and safer solution.

This framework allows operators to balance data quality needs, operational efficiency, and HSE excellence.

Looking Ahead

Eliminating radioactive sources from the drilling BHA helps deliver reliable measurements without the complications of radioactive source handling, marking a key step toward safer, cleaner, and more efficient drilling. As innovation is the backbone of the oil and gas sector, technologies that simplify operations while reducing risk will see an increased adoption. In an era where efficiency and environmental responsibility are not competing priorities but rather complementary, the removal of radioactive materials from the BHA sets a new industry benchmark—one that underscores a commitment to progress, performance, and the protection of both people and the planet.

Vivek Agarwal is the Product Champion at one of the world’s largest oilfield services companies, bringing over 17 years of diverse experience in the energy industry. He holds an MBA degree from Rice University, Texas, USA and an engineering degree from Indian Institute of Technology Kharagpur, India, and began his career as a field engineer working both offshore and onshore fields.

Throughout his career, Vivek has taken on multiple roles spanning operations, engineering, sales, marketing, and product management. His extensive experience across Asia, North America, and South America has allowed him to collaborate with leading energy companies, driving innovation and delivering impactful solutions. With a strong blend of technical and commercial acumen, Vivek continues to play a key role in shaping technology portfolio and supporting global energy initiatives.