The upstream sector is witnessing considerably more implementations of the Industrial Internet compared to other oil and gas sectors. This is driven by the need to reduce operational risks and maximizing returns from their assets through digitalization, according to GlobalData, a leading data and analytics company.

The company’s latest thematic report: ‘Industrial Internet in Oil & Gas’ reveals that the adoption of the Industrial Internet would enable companies in digitalizing oilfield operations and creating digital twins to reduce risks and optimize performance.

Industrial Internet has the potential to transform traditional processes and workflows and boost the technological capabilities of oil and gas firms. This could help them achieve two primary objectives: firstly, companies would be able to overcome operational challenges while venturing into new frontiers in search of hydrocarbon resources; and secondly, Industrial Internet adoption will improve productivity and efficiency, thereby strengthening market competitiveness in a challenging environment.

Ravindra Puranik, Oil & Gas Analyst at GlobalData, comments: “In general, adoption of the Industrial Internet would make organizations more dynamic and adaptable to external factors. This concept is expected to play a central role in simulation and modeling of projects against different market scenarios, optimizing inventory levels, demand forecasting, decision support, and logistics optimization, and setting up long-term objectives for an organization.”

Adoption of digital technologies has surged of late, largely as a reaction to the crash in crude oil prices. However, companies have been quite methodical in their approach to enable this transformation and ensuring maximum possible value can be derived through Industrial Internet implementations.

Puranik explains: “This is particularly evident in the case of digital twins, wherein companies have chosen fields that have recently entered into production or are on the verge, to allow for the integration of advanced sensors and connectivity with oilfield infrastructure for remote monitoring and analysis. To highlight one such instance, BP created a digital twin at the Claire Ridge project in the North Sea, which started producing oil in 2018. The company was assisted by WorleyParsons in the creation of a digital replica of the field.”

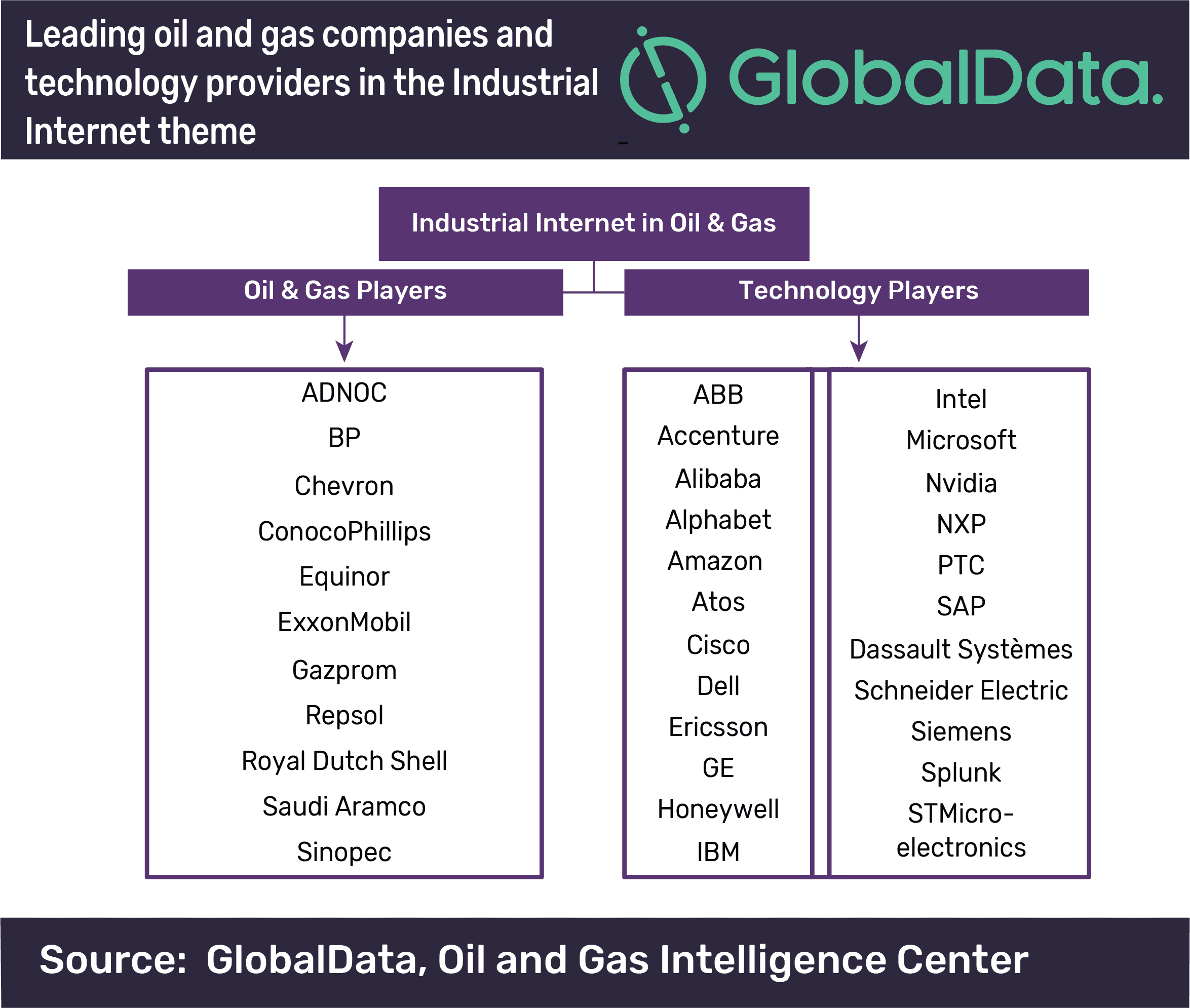

GlobalData’s thematic research identifies oil and gas companies, such as BP, Shell, Chevron, ExxonMobil, ConocoPhillips, Gazprom, Repsol, Equinor, Saudi Aramco, Sinopec, and ADNOC as the major players in the adoption of the Industrial Internet theme in the oil and gas industry. These companies are adeptly assisted by technology providers, such as Microsoft, IBM, Amazon, PTC, Cisco and Intel, which are gradually assuming leadership in delivering Industrial Internet solutions to the oil and gas industry.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.

![Why Enhanced Geothermal Energy Could Be Your Next Smart Investment [2025 Guide]](https://b1006343.smushcdn.com/1006343/wp-content/uploads/2025/06/Why-Enhanced-Geothermal-Energy-Could-Be-Your-Next-Smart-Investment-2025-Guide-500x280.jpg?lossy=2&strip=1&webp=1)