Following the rapid adoption of virtual reality (VR) technology in consumer markets, the oil and gas industry is witnessing wide-scale deployment of this technology across its value chain, according to GlobalData, a leading data and analytics company.

The company’s latest thematic report, ‘Virtual Reality in Oil & Gas’, explores how VR is finding its way into upstream, midstream and downstream sectors with applications in the simulation of new processes, analysis of project designs, reviewing of maintenance requirements and planning disaster responses.

Ravindra Puranik, Oil and Gas Analyst at GlobalData, comments: “Over time, this technology will transform oil and gas processes and workflows and help create new growth opportunities for organizations.”

VR provides an interactive experience for oil and gas processes within a simulated environment and presents a superior alternative to images, charts and schematics in the design and planning of different activities in the oil and gas sector. For example, if a team of geologists, geophysicists, drilling engineers and technicians are tasked with analyzing vast acres of seismic data in order to select a drilling location, a 3D model of the subsurface can be rendered using VR for observing the terrain, undulations and fractures in the geologic formation. It creates a virtual walkthrough of the subsurface that can guide decision-makers in the evaluation of the pros and cons of proceeding with drilling operations.

Puranik continues: “VR and 3D simulations allow employees to interact with field equipment in a virtual world. Using the VR system, an employee can get hands-on training on different kinds of equipment and devices without affecting normal work routines. Furthermore, it is equipped to replicate a wide range of emergency situations that employees could potentially face in real-life while working onsite with heavy machinery, thus ensuring they are ready to deal with any unforeseen event.”

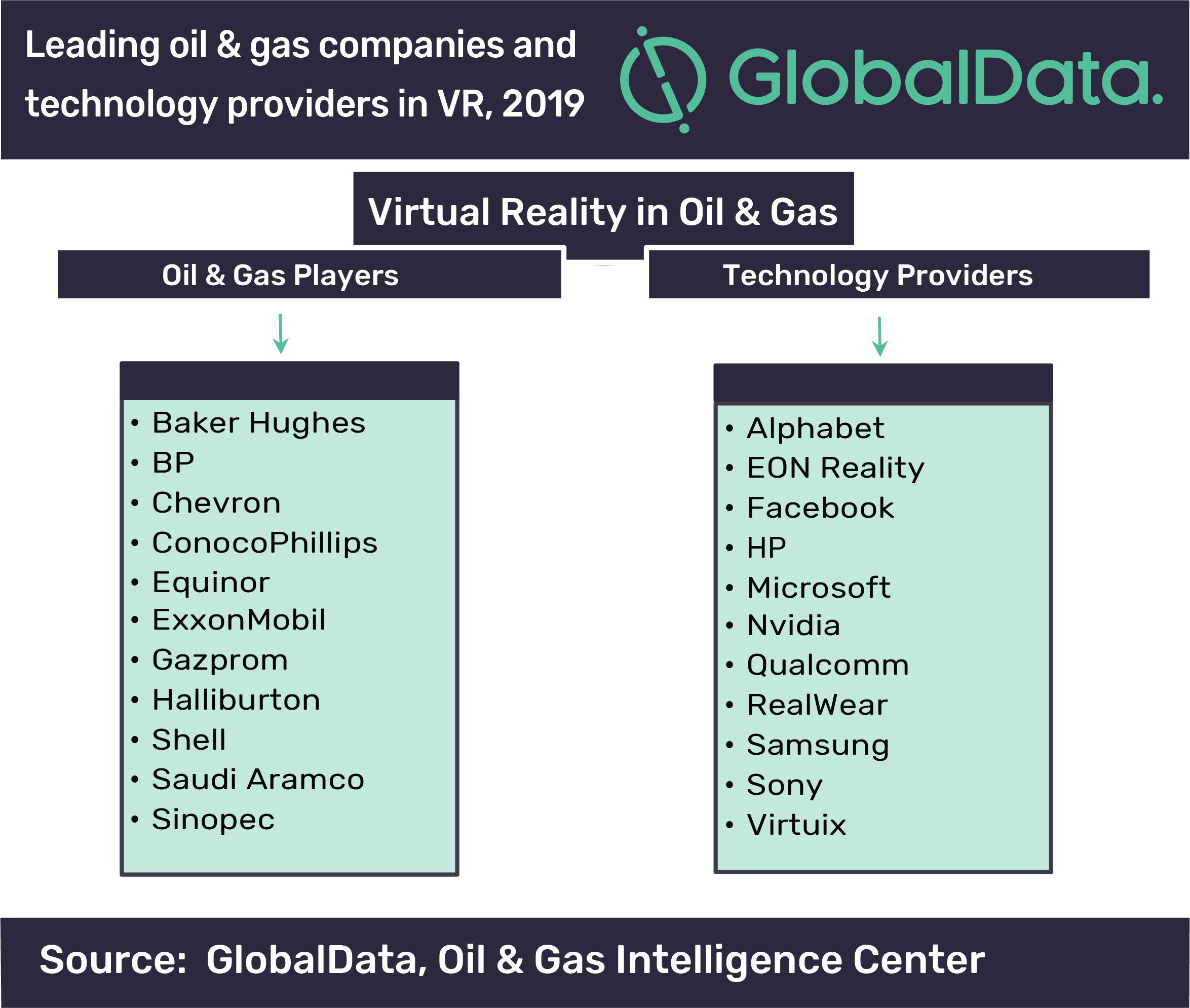

GlobalData identifies Baker Hughes, BP, Chevron, ConocoPhillips, Equinor, ExxonMobil, Gazprom, Halliburton, Shell, Saudi Aramco and Sinopec as among the leading adopters of VR technology in oil and gas operations.

The oil and gas industry faces a unique challenge as many of its facilities are in remote locations around the world. Inaccessible terrains and harsh weather conditions compel companies to incur significant costs to keep operations running in those facilities. VR has the potential to create virtual rigs using 3D simulation techniques to expose the workforce to the hazards of field operations in a cost-effective, yet risk-free way for the company. With advancements in VR technology, the cost to plug an expert into VR system has become more economical than sending them to the facility.

Puranik adds: “Digital twin is emerging as a prominent use case for VR in oil and gas operations. This approach is focused on enhancing business processes through data visualization. VR-powered digital twins are helping operators create and fine-tune plant designs, processes, and workflows and monitoring operational performance to identify improvement opportunities.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.