Any oil and gas company that has a fleet to help carry out its business knows all too well how hidden expenditures can significantly eat away at profits. From wasted fuel to unnecessary maintenance costs, inexact management of a fleet can bring a heftier price tag.

The good news is that it’s easy to pry these types of costs out of hiding with fleet management software that tracks the actions of both vehicles and drivers. Feeling blindsided by “hidden” costs no longer has to be the norm for oil and gas companies operating fleets.

Real-time data and measurements can help fleet managers zero in on the metrics that are causing costs to rise. A better understanding of the numbers behind fleet operations is pivotal to keeping fleets running as efficiently as possible and maximizing their return on investment.

Data analytics and algorithms can help companies detect and address trends that could cause a future increase in costs. For example, the data collected by the fleet management software can help determine the most cost-effective life cycle of a vehicle.

There are four easily avoidable “hidden” costs.

1. Failure to adhere to the recommended preventative maintenance schedule

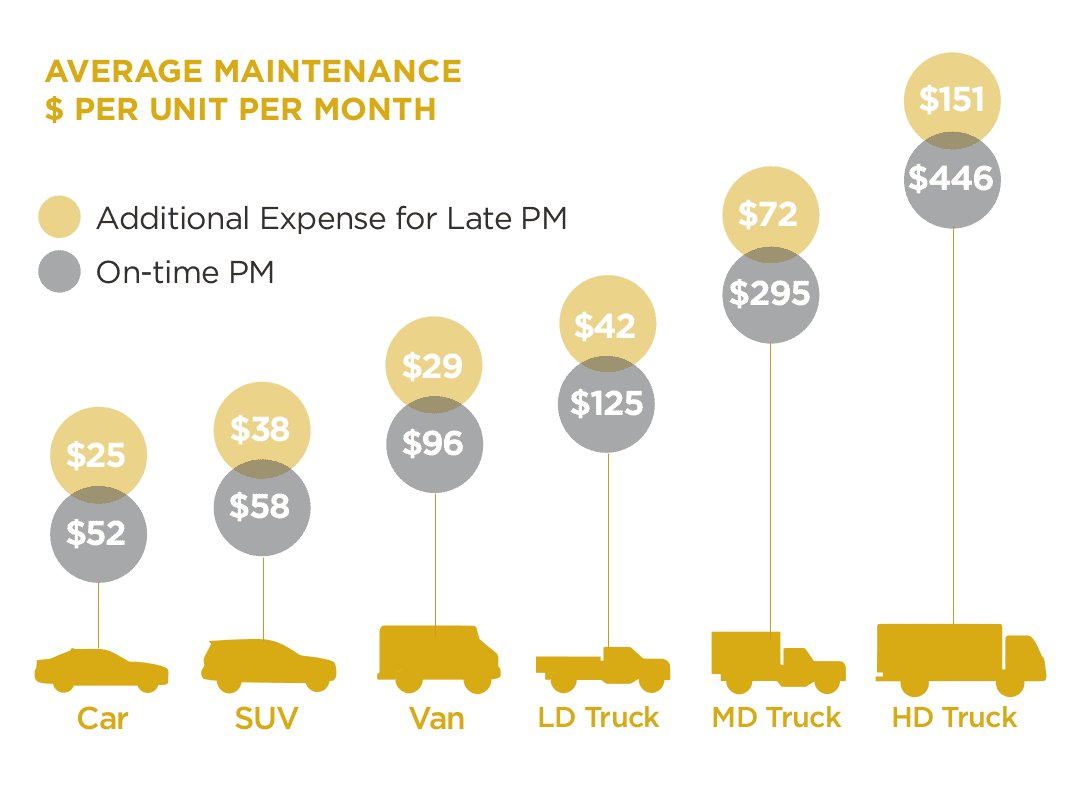

Data shows that vehicles that failed to undergo regularly scheduled maintenance incurred service costs that were 47 percent higher than vehicles that received their preventative services on time. In an analysis of 167,893 vehicles whose preventative maintenance was delayed, owners spent a total of nearly $8 million more than on-time maintenance would have cost. Though it seems like a cost-effective solution to go as long as possible without servicing the vehicles, skipping regular servicing causes tire and repair costs to be much higher than if the vehicle was serviced on time. For example, tires wear out quicker if tire rotations do not occur often enough. Also, periodic visits to the mechanic allow problems to be detected early before they become exacerbated, which results in substantial long term savings. Data analytics can allow fleet managers to determine the “sweet spot” for how often vehicles should be serviced instead of relying on the arbitrary metrics of the past.

2. Poor management of fuel expenditures

Fuel costs are generally one of the significant parts of a company’s overall fleet costs. In fact, fuel disbursements make up 60 percent of a fleet’s operating budget, which means that there is plenty of opportunity to save valuable dollars. It is vital that companies have strict policies regarding fuel card usage, desired grade of fuel, preferred fuel providers, and best practices to conserve fuel to prevent fuel costs from being higher than necessary. Behavioral changes by drivers that are as simple as following the speed limit can play a large role in reducing fuel costs. Going 55 mph instead of 50 mph costs a company 17 cents more per gallon of gas. Fleet management software effectively monitors fuel consumption and determines which factors are causing fuel costs to rise. One company that used the fleet management software to collect and analyze data to create a fuel-usage improvement plan saved $1 million in 18 months.

3. Excessive idling by vehicles

Idling is not only harmful to the environment but also to a company’s budget. Vehicles that idle more than necessary experience higher fuel and maintenance expenses. In just one hour, an idling engine can use more than a half-gallon of fuel and can cause the equivalent of 30 miles of engine wear and tear. Drivers who let their vehicles idle prevent the engine from reaching its optimal cylinder pressure and temperature causing a large amount of costly maintenance issues. Telematics and data management solutions enable fleet operators to monitor idling and identify which drivers do not practice the company’s idling management policies.

4. Know when to sell

A common mistake made by fleet companies in the oil and gas industry is a failure to grasp the importance of the remarketing stage when it comes to maximizing a vehicle’s return on investment. It is of the utmost importance that data and algorithms are used to determine the most strategically effective lifecycle of a vehicle. Vehicles that are operated past their useful life cost more in maintenance than they contribute to the fleet. Vehicles should be retired and sold when servicing costs and downtime start to increase but resale costs are still meaningful. A consequence of remarketing a vehicle too late in its lifecycle will prevent it from being sold for a price that justifies the initial investment.

While operating a fleet will always be an incredibly expensive venture, using data to analyze day-to-day operations will play a big role in maximizing and maintaining profits. Fleet management no longer has to rely on using arbitrary metrics and numbers as it was done in the past. Using real-world data allows managers to form policies and practices that are best for their business’s bottom line.

By Don Woods

Don Woods is the director of information technology at ARI in Mount Laurel, New Jersey, the world’s largest family-owned fleet management company, managing nearly 1.5 million vehicles in North America, the UK and Europe.